radios1

Elite Member

something this dangerous is designed by mechanical engineers, and then tested for flaws in design, under safe conditions.. let us know somehow if you get hurt by this!!..

All valid reasons lol.I went full width for a few reasons.

1. I was scared it wouldn’t be rigid enough without it.

2. I was mostly just copying Woods design.

3. The though had never occurred to me. Lol

something this dangerous is designed by mechanical engineers, and then tested for flaws in design, under safe conditions.. let us know somehow if you get hurt by this!!..

something this dangerous is designed by mechanical engineers, and then tested for flaws in design, under safe conditions.. let us know somehow if you get hurt by this!!..

But mostly I’m just enjoying playing with my toys.

Ah got ya, i would definitely invest in some standard size annular cutters, perfect for what you're doing and way less of a pain then using the boring head!That piece is an off cut of the 4x4 used for the main beam.

It was at the last minute that I found out I could piggy back on one of the work orders. So I only had 1 evening to model the parts I needed. So I stuck with the parts I hadn’t bought materials for already.

I’ve only been with this company since January so I’m trying to keep my l nuisance level to a minimum.

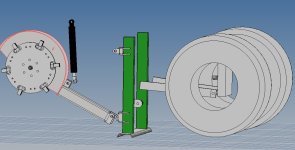

View attachment 654231

Here’s a hasty model of what’s going on.

It’s what I do all day, and it’s the last thing I want to do when I punch out. so don’t judge it on its crudeness.