motownbrowne

Elite Member

- Joined

- Dec 30, 2013

- Messages

- 2,613

- Location

- river falls, wi

- Tractor

- Kubota mx4700 HST, New Holland TC-29D

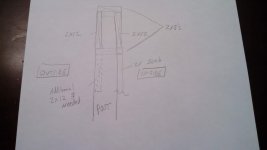

I bought a few pole barn posts last year. They are foundation grade treated 2x6s laminated together for 5, 6, and 7 feet (each board), then they are each notched into a regular 2x6. I found them at a surplus building supply store for $18 each. They're 18' long.

I've never seen them at a Menard's or anything, but someone makes them and maybe they can be found new at a reasonable price. The treating is rated to go in the ground, they are stronger than a 6x6, and have more surface area to absorb the treating.

I've never seen them at a Menard's or anything, but someone makes them and maybe they can be found new at a reasonable price. The treating is rated to go in the ground, they are stronger than a 6x6, and have more surface area to absorb the treating.