Blade Breaker

Gold Member

- Joined

- Mar 12, 2014

- Messages

- 251

- Location

- Southern MN

- Tractor

- 5115M, 825I S.E., 1445 S2, F932, M, H, 8N,

You are using the term pulsed weld to describe this. That is incorrect. This is start, stop, repeated. Others are correct saying this is not a good method for structural welds due to many reasons. A welding machine that has a pulse setting will not turn off the welding current during the pulse. It has a background current that keeps the puddle molten and then a higher peak current. The idea is to reduce the total amount of heat into the base metal while still maintaining good penetration in the weld. I have found this feature to be nice but not a value unless used in high production welding environments which I do not do. I do have this feature on both my machines but rarely use it.

Watertight is no problem, it's a pretty quick pulse, about as quick as you can work that trigger finger. I have never quantified it but guessing from memory it's about 2/3 on, 1/3 off.

Why watertight, does it hold liquid? Or just to exclude water so it doesn't leak rust stains or fill with ice? You can do that with paint if the weld is decent.

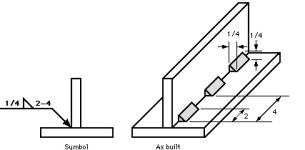

This pic is 1" x 1" x .065" (=16ga) pulsed with .030 wire. You can make it a little tighter with .023 wire. I think you'll pick it up pretty fast.