OP

joshuabardwell

Elite Member

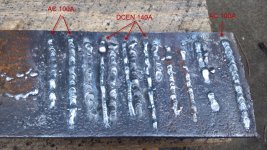

your dc welds are cold.weld a few passes with the dc turned all the way up.then swap the cables and try a few more.post them and let me look . also clean your welding plugs.i use a car battery brush.check your 220 receptacle and make sure it has enough voltage.

Yup. Cold is exactly what I was thinking when the metal was beading up. Molten metal flows to the heat, so if it is beading up it means that the work piece is not getting enough heat. For what it's worth, I tried turning the welder all the way to its hottest setting, and the results were the same, so I don't think that's the issue. I have also checked the output of the receptacle, and it's dead-on 240.