adlertom

Silver Member

- Joined

- Aug 17, 2004

- Messages

- 197

- Location

- Southern Wisconsin

- Tractor

- New Holland TC33DA hydro w/supersteer

I would like to change the engine oil in my TC33DA with a Shibaura N843 3 cylinder diesel engine.

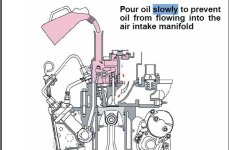

I've read that when adding the new oil, it should be added slowly to avoid engine damage. Apparently if added to quickly, the oil can find its way into the intake manifold.

So, this makes me a bit worried. About how slow do I need to add the oil? How fast is "too fast"?

I've read that when adding the new oil, it should be added slowly to avoid engine damage. Apparently if added to quickly, the oil can find its way into the intake manifold.

So, this makes me a bit worried. About how slow do I need to add the oil? How fast is "too fast"?