First off, Congratulations on the new mill! It is just as exciting to saw that first board off a new mill as it is to scoop that first pile of dirt with a new tractor! Like you, I started out with an Alaskan Mill, only, you had much more patience than me, I upgraded shortly after milling that very first (and only) log. :laughing:

After a short period, I ended up with a Woodmizer LT15. I only mill for myself and for the most part, the mill is always stationary, I rarely move it other places. I'll post some of my comments to your questions and try to add a few tips that I've learned over the years of milling off and on.

As mentioned, I built some additional track and will be setting the whole unit up on some nice straight 20' long 6x6 posts. I'll probably set some more 6x6 at a right angle to the mill as a place to set logs to bet rolled on the mill.

I would normally never point this out as it seems "nit picky", but since you now have a sawmill, I figure you should know...

A horizontal timber is never referred to as a "post".

So, my questions for those will sawmills (stationary or portable, circular or band):

-What kind of equipment do you use to get your logs from the stump to the mill?

I almost always use my grapple. Usually I can carry the logs in the grapple and place them directly onto my "log bunks". If they are too heavy (mostly to do with length) or they are too long to carry out of the woods without running into trees, I'll use my log arch, although this is rare. The few times I've had to carry numerous logs longer distances, I've used my tractor and grapple to load the logs on a full size trailer, and then the same method to offload them at the mill. I've also used a dump trailer once which wasn't mine. That was a really slick setup but only good for logs less than 14' or so.

I would not have a sawmill without a FEL grapple. (I chose the specific grapple I have based on uses for the mill, let me know if you want "reasons why".)

Here is what I used prior to my new tractor and grapple...

It is 10 times faster with the grapple, and I never have to leave my seat

-What kind of method or layout do you use to efficiently separate/stack/move lumber, slab wood, sawdust etc away from the mill?

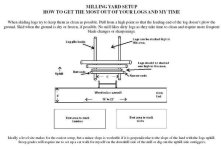

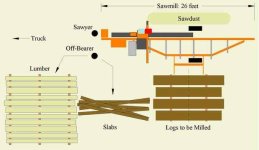

Here is what works pretty well for me. These are not my pictures, but I find them useful, and they were posted with permission to use elsewhere. I based my mill setup on these suggestions.

Depending on how your site is laid out, or if you have a helper, you may find this works well for you. Otherwise, it's a good start if nothing else.

Milling efficiently is similar to splitting firewood efficiently, material handling (onloading and offbearing/stacking) has more to do with efficiency than the ability of the mill. No matter how nice of a log splitter I have, I still have to load the rounds, move the splits, and stack them properly. Same with milling.

-I'll be stacking and stickering the lumber outside for now, what do you use as a good flat base for your lumber? To cover your lumber stacks?

Outside is fine, that is where most of us stack our lumber. If I'm storing some timbers or lumber outside and I don't want them to be discolored by sunlight, then I'll cover them with a tarp, elevated off the timbers, and allowing airflow on all 4 sides. A tarp isn't ideal but it works for short periods. Otherwise though, I really don't cover my lumber, however I always sticker it. Stickering is much more important than covering. Always sticker your lumber, especially pine in really hot/humid weather. Pine will start to "bluestain" within a matter of days if it is not stickered.

I use green stickers when sawing pine, and saw my stickers from the "waste" or when edging boards. Be sure all your stickers are the same thickness in one dimension and always use that dimension for your stickers (within the same row).

You will get stains when using green stickers, and if your using it for framing lumber that will be covered up it is fine. It doesn't affect your lumber structurally but keep in mind, even if you plane the wood, it may not come out. I use dry stickers for timbers or wood that will be used and seen, like flooring.

I built quite a few "pallets" for my longer wood, mostly so I could move it around if needed. If your not worried about moving it around, then a flat base of any sort, elevated off the ground will work well. Try to elevate the base of the stack about a foot or more. You'll want to be able to get either a push mower or weed wacker under there if the grass starts growing high around the edges.

-Any other advice for a first time sawyer?

This really is an entire forum all on it's own. Spend some time on forestryforum.com, go to google, and search things like "first time sawyer site:forestryforum.com" or "manual mill site:forestryforum.com" and so on.

Check out Sawmill and Woodlot Magazine. There are lot of good articles on their website as well.

When your skidding your logs, keep them off the ground if possible, you'll dull the blade much quicker with dirty logs. This is the one reason I don't own a skidding winch.

When you pile your logs near the mill, always pile them so the small end is towards the front of the mill.

You'll want some sort of log bunks, weather it is a permanent set of bunks set in the ground, or something more temporary like 2 sides sawn off of larger logs. This is what I use. If you have some older logs, or ones that won't produce good lumber, saw off one side on the mill, flip the log 180, saw the other side down, and use this as your log bunks. I used my chainsaw to cut an angle at the beginning of them to help roll logs on, although I never use it since I place them on the bunks with the grapple.

If you don't have a level site, put the sawmill "downhill" and perpendicular to the hill.

Keep your log bunks a good 6' apart from each other, so you can drive the tractor between them to place logs on the bunks. Before I had my grapple I used a set of 3 point forks to move around my logs. It worked, but I'll never go back to it. :laughing:

Your going to want a level site if you have one. All 4 sides of the mill can be used. I have a pile of sawdust at the "end" of the mill. I use a snow shovel to push the sawdust into the pile. After sawing your first few logs, and getting a good little pile of sawdust built up at your feet, don't remove that sawdust, instead spread it around a little to create a "walking path" built of sawdust, your feet with thank you. It's like walking back and forth on one GIANT dr. Scholls insert.

If you dont' already have one, get a cant hook or log peavey :thumbsup:

-Matt