mark in portugal

Gold Member

I recently bought a second 20' container for the wife to store her works in; since she's an artist and particular about things, hers got painted inside and outside.

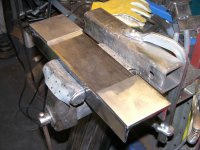

I also laid aluminum skinned asphalt roofing felt on top.

I maintain some old barges, and I'm used to painting large objects; still painting a container is a big pita.

I used Jotun marine paint, which comes in big cans and is a bit cheaper than other metal paint; but it's a LOT of surface and a lot of paint.

The Jotun primer goes over everything; old metal, old paint, it's great stuff. I just clean it for a good long time with a big 8hp high pressure cleaner, then roll it on. It can be sprayed with an airless, but I don't have one of those.

The coregations have to be rolled 1 by 1. I used a big roller and cut it short so it would fit. I'm fast with a roller, but this job took a lot of time.

Conclusion; it looks great and all, but painting an old sea container is a job done for love, not practicality. We live in a 'nature' reserve and building any new permanent structures isn't allowed.

I also laid aluminum skinned asphalt roofing felt on top.

I maintain some old barges, and I'm used to painting large objects; still painting a container is a big pita.

I used Jotun marine paint, which comes in big cans and is a bit cheaper than other metal paint; but it's a LOT of surface and a lot of paint.

The Jotun primer goes over everything; old metal, old paint, it's great stuff. I just clean it for a good long time with a big 8hp high pressure cleaner, then roll it on. It can be sprayed with an airless, but I don't have one of those.

The coregations have to be rolled 1 by 1. I used a big roller and cut it short so it would fit. I'm fast with a roller, but this job took a lot of time.

Conclusion; it looks great and all, but painting an old sea container is a job done for love, not practicality. We live in a 'nature' reserve and building any new permanent structures isn't allowed.