(Oh, BTW - now you can join the "pick on Shiny Steve" club,)<<<<<<<<<<<Oh boy sign me up. Wouldn't something like this blaster be more mentally satisfying to get shiny mental ready for tig welding, hummmmmmm pick pick pick>>>>>>>>>>>Spot Blaster - Speed Blaster - Abrasive Blasting Gun >>>>> Soda Blaster & Media Blaster In Action - The Small Job Blast System from Eastwood - YouTube

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Container Weld Shop build -

- Thread starter BukitCase

- Start date

- Views: 112211

More options

Who Replied?

/ Container Weld Shop build -

#241

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

My blaster's exactly like that Eastwood; I haven't tried soda on it, but it's kind of a joke using blasting sand on anything too big for a cabinet - gettin' paint off a valve cover is NUTTIN' compared to tryin' to convince mill scale you actually MEAN it  - I used the blaster for about a hour and a half on the I beam I'm using on the HF crane kit, got about a foot and a half on ONE SIDE and used about 25# of sand, made a mess, gave up and went back to the 9" grinder and a 8" coarse wire brush.

- I used the blaster for about a hour and a half on the I beam I'm using on the HF crane kit, got about a foot and a half on ONE SIDE and used about 25# of sand, made a mess, gave up and went back to the 9" grinder and a 8" coarse wire brush.

Also, any media that'll cut mill scale with a blaster leaves a REAL rough surface that'd still look like CRAP with a coat of paint (or three)...

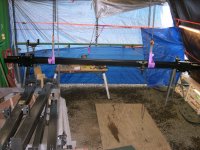

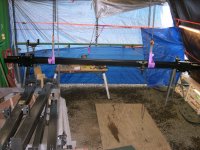

Got the pieces welded up for the "simpler/quicker/cheaper" version of the weld container's "porch roof" done, painted and the 9'x11' tarp clamped up; Guess which side the weather comes from - one less distraction on the way to actually doing what the title of this thread claimed eons ago - manana I can get back on the corner braces for the HF crane... Steve

- one less distraction on the way to actually doing what the title of this thread claimed eons ago - manana I can get back on the corner braces for the HF crane... Steve

Also, any media that'll cut mill scale with a blaster leaves a REAL rough surface that'd still look like CRAP with a coat of paint (or three)...

Got the pieces welded up for the "simpler/quicker/cheaper" version of the weld container's "porch roof" done, painted and the 9'x11' tarp clamped up; Guess which side the weather comes from

Attachments

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

I learned a while back, that if I can't recycle my blasting media, I'm going to other processes to prep my parts. This means everything I can't fit in my HF cabinet. I bought the HF 40lb blaster and don't use it because it goes through way too much media that becomes a mess that can't be easily cleaned up.

4� lb. Pressurized Abrasive Blaster

4� lb. Pressurized Abrasive Blaster

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Yup, same here - I've resisted getting the HF blaster, no room (yet) for even THAT size.

Once I get THAT problem addressed, I have one of those oval ended diesel tanks (freebie) that's about 400 gallons - the "plan" is to stand it up with the ovals to the sides, cut it horizontally across the center, lower half mounts on a STURDY stand, upper half piano-hinged at the rear, removable grate flush with lower half - couple "trap doors" on both ends of the top half for "pass-through" operation (curtains inside for deflectors - think "long pipe/beam/channel", etc) - metal cyclone vac for recycle, whole thing positioned so I can load/unload it with the FEL.... (did I mention the "later" part??!? - as in, maybe NEVER, but it's fun to kick it around in my demented mad scientist-type brain)

Speakin' of prepping, I should go do more of that; still got all the pieces for the HF crane corner braces to do (second pic, post#236, plus 4 pcs 2" tube)... Steve

Once I get THAT problem addressed, I have one of those oval ended diesel tanks (freebie) that's about 400 gallons - the "plan" is to stand it up with the ovals to the sides, cut it horizontally across the center, lower half mounts on a STURDY stand, upper half piano-hinged at the rear, removable grate flush with lower half - couple "trap doors" on both ends of the top half for "pass-through" operation (curtains inside for deflectors - think "long pipe/beam/channel", etc) - metal cyclone vac for recycle, whole thing positioned so I can load/unload it with the FEL.... (did I mention the "later" part??!? - as in, maybe NEVER, but it's fun to kick it around in my demented mad scientist-type brain)

Speakin' of prepping, I should go do more of that; still got all the pieces for the HF crane corner braces to do (second pic, post#236, plus 4 pcs 2" tube)... Steve

You ever try these Norton Ceramic disc?>>> Airgas - NOR66261185294 - Norton(R) 4 1/2" X 5/8" 36 Grit F98 Blaze(R) Ceramic Alumina Resin Bond Fiber Disc (25 Per Pack)

Heres a youtube demo, looks impressive on rebar, wonder how it does on mill scale, they might make shiny metal shinier, easier and quickerah.... You will TRASH your GRINDING DISKS after you WATCH THIS! NORTON!! - YouTube

Heres a youtube demo, looks impressive on rebar, wonder how it does on mill scale, they might make shiny metal shinier, easier and quickerah.... You will TRASH your GRINDING DISKS after you WATCH THIS! NORTON!! - YouTube

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

I haven't tried the Nortons, looks like they want over $40 for the backing pad - actual disks aren't too high, tho - I do have a couple of the 3M "cubitron II" disks, haven't tried those yet either. Still got 3 or 4 boxes of those CGW flap disks, maybe I'm just afraid I'll wanna throw 'em away if I try somethin' that actually WORKS

Guess I could find at least ONE of the dozen or so grinders that isn't doin' anything ATM (no, NOT the cash machine - more like a PAIN machine :laughing and try the Cubitrons; if they work better, I'll probly not kick myself as HARD as I woulda if I'd used up all the CGW's...

and try the Cubitrons; if they work better, I'll probly not kick myself as HARD as I woulda if I'd used up all the CGW's...

'Sposed to get some SERIOUS "sideways rain" next couple days, guess I'll find out how well my "el cheapo porch roof" is gonna hold up - also opened up the box on that HF crane I'm doin' the mods for, wanted to make sure I wasn't making something that wouldn't fit ANYTHING -

-

Found the "assembly" section, first two items -

1. More than one person will be

needed for assembly.

2. Use a large, clean and uncluttered

area for assembly.

First thought - I'm SCREWED...

Second thought - Dang good thing I'm a sneaky, underhanded mad scientist type that's only a LITTLE bit more stubborn than a mule

Third thought - ANOTHER good thing I ALWAYS have fun, no matter what I'm doin' - 'cause I ALWAYS seem to have at least three more irons in the fire than I have firewood - Later, gotta go do crazy stuff... Steve

- Later, gotta go do crazy stuff... Steve

Guess I could find at least ONE of the dozen or so grinders that isn't doin' anything ATM (no, NOT the cash machine - more like a PAIN machine :laughing

'Sposed to get some SERIOUS "sideways rain" next couple days, guess I'll find out how well my "el cheapo porch roof" is gonna hold up - also opened up the box on that HF crane I'm doin' the mods for, wanted to make sure I wasn't making something that wouldn't fit ANYTHING

Found the "assembly" section, first two items -

1. More than one person will be

needed for assembly.

2. Use a large, clean and uncluttered

area for assembly.

First thought - I'm SCREWED...

Second thought - Dang good thing I'm a sneaky, underhanded mad scientist type that's only a LITTLE bit more stubborn than a mule

Third thought - ANOTHER good thing I ALWAYS have fun, no matter what I'm doin' - 'cause I ALWAYS seem to have at least three more irons in the fire than I have firewood

Last edited:

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

I use the cubitron little discs. Love them.

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

What do you use those little 2" disks on, an air die grinder? Bet that'd be good for tight places - The couple Cubitrons I still haven't tried are 5" zip disks, .045" thick - and I found out I lied about the OTHER zip disks, I used to use Walters but this batch are CGW, just a tiny bit thinner at .040". Those are the ones I've been using the angled light/fast touch on to bust thru mill scale - works as well as anything I've tried...

On the subject of the HF crane - There's been a breakout -

But they didn't get far before I had 'em all lined up -

I'm pretty sure they'll wanna "bolt", but there's matching gallows waitin' fer 'em...

OK, I'll be good now.... (maybe...)

On the subject of the HF crane - There's been a breakout -

But they didn't get far before I had 'em all lined up -

I'm pretty sure they'll wanna "bolt", but there's matching gallows waitin' fer 'em...

OK, I'll be good now.... (maybe...)

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

I'm appreciating your shop more and more.

Yes, the small diameter disks have their space. for me, sometimes I need to grind a small area with a bit of precision or limited access. In those cases, they have been the ticket!

Yes, the small diameter disks have their space. for me, sometimes I need to grind a small area with a bit of precision or limited access. In those cases, they have been the ticket!

I'm appreciating your shop more and more.

Yes, the small diameter disks have their space. for me, sometimes I need to grind a small area with a bit of precision or limited access. In those cases, they have been the ticket!

I just had encounter of how nicerah it would've been if had a 2'' sanding disc, instead I tried to smooth out the best I could with a die grinder. Down the shipyard we use 5'' Cubitron grinding wheels and sanding disc, the trouble I see with the sanding disc is the edge, 1/2'' thereabouts wares out I think a little too fast, but sanding down welds/burning slag yes they work good, for sanding paint not so good.

I was hoping for some west coast trail test and reviews on the the Norton Ceramic disc before I shell out $4-5/sanding discs. You know for making and producing a good test and review, someone needs to do the test that likes making shiny metal and a lot of it. :stirthepot:

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

"I was hoping for some west coast trail test and reviews on the the Norton Ceramic disc before I shell out $4-5/sanding discs. You know for making and producing a good test and review, someone needs to do the test that likes making shiny metal and a lot of it. "

Probly gonna be a while; I'm kinda on a roll (no sesame seeds, tho - Been playin' with the HF gantry more today, you'll probly be in bed before I upload the pics. Instructions say to "use your helpers"... what few "helpers" I had are either still workin', dead, or moved to Mexico

- Been playin' with the HF gantry more today, you'll probly be in bed before I upload the pics. Instructions say to "use your helpers"... what few "helpers" I had are either still workin', dead, or moved to Mexico

So it's a good thing I have my OWN "helpers", including several straps, shackles, 3 or 4 chain falls, blocks, sawhorses, etc... That's just the "teaser", but as the news liars say, "Pics at eleven" :laughing: ...Steve

Probly gonna be a while; I'm kinda on a roll (no sesame seeds, tho

So it's a good thing I have my OWN "helpers", including several straps, shackles, 3 or 4 chain falls, blocks, sawhorses, etc... That's just the "teaser", but as the news liars say, "Pics at eleven" :laughing: ...Steve

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

OK, so it's a little past eleven (here, anyway) - Oh well....

Here we go; first, the (upgraded) I beam, ready to attach the legs -

Then a closeup of the heavier post mount -

First and second posts attached -

Sometimes things need a friendly tap to get that last bolt to line up

A piece of conduit across the post bottoms, to make sure there's no twist -

Ready for feet -

The hardware

18mm bolt heads? Really??!? Smaller ones were 16mm, I actually found 1 socket in each size, had to break out the "metric fitzall" for the other end -

Got lucky on the 8" casters I ordered, bolt holes were a perfect match to the HF 5" that came with the crane - I ordered these from Surplus Center - 8" X 2" Colson Swivel Plate Caster w/ Wheel Brake 881S��G�S | Plate Casters | Casters | Wheels | www.surpluscenter.com - rated 1000 lbs each, should work better on gravel. Comparison -

Few more pics comin' up... Steve

Here we go; first, the (upgraded) I beam, ready to attach the legs -

Then a closeup of the heavier post mount -

First and second posts attached -

Sometimes things need a friendly tap to get that last bolt to line up

A piece of conduit across the post bottoms, to make sure there's no twist -

Ready for feet -

The hardware

18mm bolt heads? Really??!? Smaller ones were 16mm, I actually found 1 socket in each size, had to break out the "metric fitzall" for the other end -

Got lucky on the 8" casters I ordered, bolt holes were a perfect match to the HF 5" that came with the crane - I ordered these from Surplus Center - 8" X 2" Colson Swivel Plate Caster w/ Wheel Brake 881S��G�S | Plate Casters | Casters | Wheels | www.surpluscenter.com - rated 1000 lbs each, should work better on gravel. Comparison -

Few more pics comin' up... Steve

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Here's the last batch; gettin' tired just remembering today :laughing:

First side ready to tip up -

The second side, ready to tip up -

And the "money shot" -

I actually added the other two diagonal braces AFTER tip up, they would've interfered with the sawhorses otherwise.

The new heavier beam is also longer, gives me 2 feet more between posts (needed for some of the operations I need to do on the 580B) - the casters raise things by 3", don't care 'cause even with the smaller ones it wouldn't go thru a normal garage door anyway - the area the crane's in now has 11' headroom and the crane will extend to 150" (AKA, 12'6" or 3,810mm )overall, so my roof is the limiting factor in that area.

)overall, so my roof is the limiting factor in that area.

Next I'll get the corner braces done, then add the 1 ton electric hoist (more mods so THAT'll work like I want it to

More "horizontal rain" forecast for manana, 'nuther good day for "shinifying" (Sorry, OP; no "golden disks" to play with, just the usual) ...Steve

...Steve

First side ready to tip up -

The second side, ready to tip up -

And the "money shot" -

I actually added the other two diagonal braces AFTER tip up, they would've interfered with the sawhorses otherwise.

The new heavier beam is also longer, gives me 2 feet more between posts (needed for some of the operations I need to do on the 580B) - the casters raise things by 3", don't care 'cause even with the smaller ones it wouldn't go thru a normal garage door anyway - the area the crane's in now has 11' headroom and the crane will extend to 150" (AKA, 12'6" or 3,810mm

Next I'll get the corner braces done, then add the 1 ton electric hoist (more mods so THAT'll work like I want it to

More "horizontal rain" forecast for manana, 'nuther good day for "shinifying" (Sorry, OP; no "golden disks" to play with, just the usual)

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

:thumbsup: :thumbsup: How is it rolling? Does it feel sturdy when moving?

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

I've only moved it a couple feet so far, still want to get the post/beam diagonal braces on before doing too much (ounce of prevention; remember, it's HF's "heavy duty"  )

)

It does move on that "semi-loose" gravel, and feels solid enough, not sure how much of that is my heavier beam and "mil spec" post mounts; from what I'm seeing, if I were going to use it ANYWHERE but nice flat concrete the caster upgrade is a MUST - the ones I linked have zerks for both axle and swivel, bolt right up and are rated 1000# each...

The height adjustments are kinda hokey, I can see a pair of air/hydraulic shop crane jacks with "two-fer" fork lift type chain doublers replacing those if I need to change heights much -

All in all, it's about what I expected; my mods will make it usable for me, stock version would be OK for stuff that isn't too wide (and on smooth concrete) - and even with the mods, it was probably a month or so quicker than scratch-built (and about 500# LIGHTER :laughing: )... Steve

Oh, and they're RIGHT (in the manual) about having "helpers" - you can see mine in all the pics, and they don't run me out of beer; they are a bit slower, but EITHER kind of "helper" is MANDATORY for assembly, unless you're Arnold (AND schizoid so you can be 2 places at once :=)

Another "helper" option - if your FEL can lift at least 600# at least 9' high. Mine can, but would've required all my "blast doors" to be open and the driveway blocked in order to have enough room; NOT a good option with our "horizontal rain" the last couple days...

It does move on that "semi-loose" gravel, and feels solid enough, not sure how much of that is my heavier beam and "mil spec" post mounts; from what I'm seeing, if I were going to use it ANYWHERE but nice flat concrete the caster upgrade is a MUST - the ones I linked have zerks for both axle and swivel, bolt right up and are rated 1000# each...

The height adjustments are kinda hokey, I can see a pair of air/hydraulic shop crane jacks with "two-fer" fork lift type chain doublers replacing those if I need to change heights much -

All in all, it's about what I expected; my mods will make it usable for me, stock version would be OK for stuff that isn't too wide (and on smooth concrete) - and even with the mods, it was probably a month or so quicker than scratch-built (and about 500# LIGHTER :laughing: )... Steve

Oh, and they're RIGHT (in the manual) about having "helpers" - you can see mine in all the pics, and they don't run me out of beer; they are a bit slower, but EITHER kind of "helper" is MANDATORY for assembly, unless you're Arnold (AND schizoid so you can be 2 places at once :=)

Another "helper" option - if your FEL can lift at least 600# at least 9' high. Mine can, but would've required all my "blast doors" to be open and the driveway blocked in order to have enough room; NOT a good option with our "horizontal rain" the last couple days...

My two helpers are now grown up and hard to get a hold of at times, my youngest son for the longest time use to think his name was Get Wood, after the past several years, I'm now thinking an oil furnace is not to far in the future.

What's with the round wheels on a gravel floor? Must be a concrete shortage out there, dont think I'd ever get use to that. Nice bunch of pictures just wish I could find more to complain about and pick apart.

What's with the round wheels on a gravel floor? Must be a concrete shortage out there, dont think I'd ever get use to that. Nice bunch of pictures just wish I could find more to complain about and pick apart.

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

"Must be a concrete shortage out there, dont think I'd ever get use to that."

Nope, just a time/energy/money/weather shortage - when the weather gets dry enough that I'm not just makin' a gumbo mess, it'll get acquainted with my Gannon box - if you notice the pics that show the upright posts for that shed, they are NOT upright; they're splayed out 4 feet at the bottoms - I purposely put an extra "U-joint" in near the top, and adjustable "elephant feet" on the bottoms - the feet are staked into the ground with rebar for now (so they won't kick out, that'd be a BIG "owieee" -

That's all so I'll have enough room to cut that floor down (and take out the 6" slope from one end to the other) - It'll need to go down about a foot so the finished slab won't cut my headroom down below 11 feet. (backhoe knuckle joint height)

Once that slab's cured, those splayed out posts (and "elephant's feet") will get lagged to the concrete and be plumb - then all the tarps will get replaced with steel-framed sliding doors.

Anybody here NOT understand yet why I'm always sayin' I'm NEVER gonna get BORED??!? :laughing: :laughing:

:laughing:

BTW, gravel beats the CRAP outa MUDDDD :thumbsup::thumbsup: ...Steve

Nope, just a time/energy/money/weather shortage - when the weather gets dry enough that I'm not just makin' a gumbo mess, it'll get acquainted with my Gannon box - if you notice the pics that show the upright posts for that shed, they are NOT upright; they're splayed out 4 feet at the bottoms - I purposely put an extra "U-joint" in near the top, and adjustable "elephant feet" on the bottoms - the feet are staked into the ground with rebar for now (so they won't kick out, that'd be a BIG "owieee" -

That's all so I'll have enough room to cut that floor down (and take out the 6" slope from one end to the other) - It'll need to go down about a foot so the finished slab won't cut my headroom down below 11 feet. (backhoe knuckle joint height)

Once that slab's cured, those splayed out posts (and "elephant's feet") will get lagged to the concrete and be plumb - then all the tarps will get replaced with steel-framed sliding doors.

Anybody here NOT understand yet why I'm always sayin' I'm NEVER gonna get BORED??!? :laughing:

BTW, gravel beats the CRAP outa MUDDDD :thumbsup::thumbsup: ...Steve

bard

New member

Do you have to do any paint touchups to prevent rust on the shipping containers that you buy?

I saw one in the background of one of our pictures and it appeared to have the original paint.

I saw one in the background of one of our pictures and it appeared to have the original paint.

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Yeah, some of 'em more than others - the more trips they've had, the worse the rust seems to be. I have a 20', 2 standard height 40's and (recently) 2 "high cube" 40 footers. The 20 is an Evergreen, and has a little more rust than I'd like; the two 40' standard heights are the oldest, and have a fair amount of rust pockets (mostly on the tops) - the two high cubes are the newest, in fact I haven't even been on top of 'em yet - they're in a temporary location for now, when the ground dries up enough (around mid June) they'll get moved to their intended locations.

The one standard height 40 I'm getting ready to turn into a weld shop got some of the rust bubbles flattened, the loose particles blown away with high pressure air and a couple cans of Rustoleum rusty metal primer last week but there's a lot MORE of that still to do. Eventually they ALL will have roofs over 'em, and I'll hose 'em down with more primer. Maybe if I ever win the lottery, I'll re-paint ALL of 'em; but with the price of paint what it is these days, it's almost cheaper to just buy a replacement when they get too bad

They'd all be in even WORSE condition if containers weren't made with Cor-ten steel and stainless - but the way they're treated by dock workers, and the salt spray they're subjected to on container ships, it's STILL a miracle they last as long as they do... Steve

BTW, welcome to TBN...

The one standard height 40 I'm getting ready to turn into a weld shop got some of the rust bubbles flattened, the loose particles blown away with high pressure air and a couple cans of Rustoleum rusty metal primer last week but there's a lot MORE of that still to do. Eventually they ALL will have roofs over 'em, and I'll hose 'em down with more primer. Maybe if I ever win the lottery, I'll re-paint ALL of 'em; but with the price of paint what it is these days, it's almost cheaper to just buy a replacement when they get too bad

They'd all be in even WORSE condition if containers weren't made with Cor-ten steel and stainless - but the way they're treated by dock workers, and the salt spray they're subjected to on container ships, it's STILL a miracle they last as long as they do... Steve

BTW, welcome to TBN...

Here are some similar links:

- Replies

- 315

- Views

- 80K