"shouldn't that winch go transverse so's not to loose travel motion, distance, length, movement?"

It could, but that can cause balance problems - with NO load, the motor is heavier than the cable spool - so if you hang the winch so THAT works, when you hang a LOAD on it that UN-balances the load on the trolley. If you remember the pics of my "mini-jib", I have that problem - somebody on a different site posted a "fix", which I shamelessly "borrowed" -

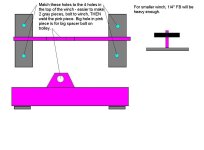

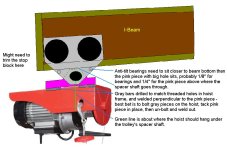

I haven't DONE that yet, and I'm not sure there's ROOM on YOUR wood beam - I just looked at one of my trolleys, and if you drilled holes for the bearings just below where the side plates angle inward it should work (on YOURS) to keep the trolley from tilting.

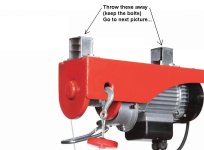

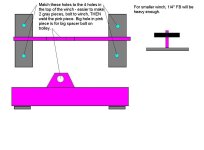

Next problem - I do NOT know what the measurements are on those 440 winches, but the 1100 lb one on my "mini-jib" actually HANGS from the long "spacer bolt" on the trolley, using those 2 brackets shown on the factory picture - if the 440 winch is SHORTER, that might not work - you'd probably need to actually TOUCH one of the small ones (dunno how close your nearest HF store is) - if that'd work for you, you should measure the total length of your trolley's big fat bolt fulla washers - here's what I mean (zoom in on that pic, I marked it up)-

"Here's an updated picture I took this past weekend, I have the chainfalls bottomed out and at times it's just barely high enough."

"Here's an updated picture I took this past weekend, I have the chainfalls bottomed out and at times it's just barely high enough."

If necessary, it looks like you could maybe raise your jib a few inches fairly simple (easy for ME to say if YOU'RE the one doin' it

"The biggest problem I have with these chainfalls if the the up&down chain only works good when its perfectly around the bundle which at most times is hard to maintain so when the chain is off to the side it jams up and that's when aggravation steps in."

"The biggest problem I have with these chainfalls if the the up&down chain only works good when its perfectly around the bundle which at most times is hard to maintain so when the chain is off to the side it jams up and that's when aggravation steps in."

Yeah, they are a PITA for that; I tend to hold BOTH of the pull chains in one hand, keep tension on 'em and stand to the side a bit and pull one while letting the OTHER one slip thru my glove - still, irritating...

"That's why if had electric winch there'd be no more Hoover jam, theridicly, but then, seems like there's always a but, I wonder what about the electric cable, will that get tangled up in the trolley, I just dont want to move aggravation from one place to the next"

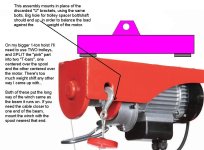

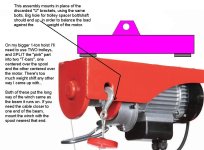

Right; the whole idea of changing things is to ELIMINATE PITA's, not ADD MORE - Here's what I did on the "mini-jib", but it's only 4 feet long; you might need "outriggers" on BOTH ends of the electric cords - it's also

how I mounted the 1100 lb winch, but the 440 might be a different distance between mounts - if so, you'd need to fab something similar to my sketches instead - notice that the cords fall BELOW the trolley...

Personally, I'd rather figger out a way to hold a cord out of the way than put up with those chains, specially the way YOU'RE havin' to do it...

Oh -

things that taught me patience -

Wife that likes horses -

Horses -

Hauling hay for horses

Cleaning up after horses

Kids (and grandkids)

Kids that're allergic to cow milk

Dairy goats (see above)

Building fences that'll keep goats in/out

Building FEEDERS that'll keep goats from WASTING most of their feed

Couple HUNDRED OTHER Things, but list is gettin' too long

Anyway, cogitate on my suggestions, they might actually WORK :laughing: ... Steve