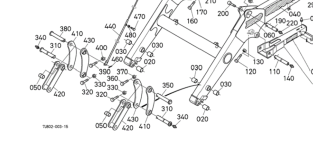

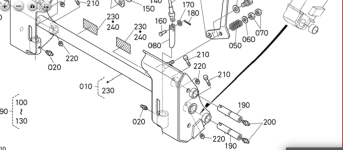

I have an '03 L48 backhoe, with roughly 1100 hours. I've now broken the hinge pin on the FEL 3 or 4 times (I think its called "Pin 7"), the pin that attaches the ram end of the cylinder to the tilt portion of the bucket attachment. This pin has a grease fitting on the end, with a hole drilled through the middle to a center portion groove. The groove has holes, where the grease expands out to lube the pivot. The pin has always broken at this groove. On my much newer 7060, the same pin has no groove, and no grease fitting....instead, the pivot is lubed by an external zerk that is threaded through the end of the cylinder ram (on top). This means the pin is a solid piece, with no extra holes or grooves (to potentiate fractures).

Here's my question. Any reason I can't simply use the newer style pin, and drill/tap the ram end on the L48 cylinder for a zerk fitting? This is how the 7060 is set up, and the pins are the exact same diameter and width. I do understand this leaves the zerk a little more exposed, but I could always tack weld a small collar around it for protection.

Here's my question. Any reason I can't simply use the newer style pin, and drill/tap the ram end on the L48 cylinder for a zerk fitting? This is how the 7060 is set up, and the pins are the exact same diameter and width. I do understand this leaves the zerk a little more exposed, but I could always tack weld a small collar around it for protection.