CDN Farm Boy

Veteran Member

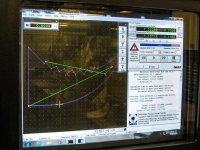

Is there a reason the layout doesn't use the existing edges of the flatstock? Seems like a waste to cutout a square piece a 1/4" in from the edge rather than just having to cut 2 sides

Is there a reason the layout doesn't use the existing edges of the flatstock? Seems like a waste to cutout a square piece a 1/4" in from the edge rather than just having to cut 2 sides

Man, I wish I had access to one of them waterjet thingies. Slick!

Looks great.

We will need some slaying photos soon.

If all goes well I'll be testing it out last week of October... pics will be posted early November. Got about 2 dozen stumps to eliminate so we'll see how I do.:thumbsup:

And the rest of the equipment too!

Holy crap Blue, nice fab work! Almost be a shame to get it dirty or scratch it

I have been getting a lot of feedback from fellow employees... everyone is excited about the fab. Got the final welding done and will post pics probably tomorrow. I need to see if I can get it into the sandblaster so I can clean it up and get a few coats of paint on it before inauguration day

The paint won't last long.

Expect a learning curve. Smaller stuff with just rip out but bigger stumps and roots require some strategy. Basically, either work at the root close in buy chewing at it or driving the point through it or alternatively, pivot the BH away from the stump and rip the root a few feet away where it is smaller. On big stumps I work around them by changing tractor position by 90 degrees after ripping the roots I can easily reach. Keep moving around rather than stretching to reach. Don't try to rip a big root with the BH fully extended as you won't have as much leverage. Use both curl on the ripper and pulling with the dipper or up with main boom. You'll probably develop your own style just try different techniques. It is not simply like digging with a narrow bucket. Also, check the stability of the stump occasionally by putting the ripper over it and pulling. Two things to look for: first is how loose it is and second is to judge where the remaining stabilizing roots are based on how it pivots. I actually only rarely use the ripper to completely remove the stump. Once it is good and loose, I turn the tractor around and get the grapple under then use low range to push and lift. Often faster than completing the job with ripper alone. Besides, you will need the FEL end to move the stump anyways so don't hesitate to use the one two punch. It can also help identify the one root that needs more ripping. On a big stump I might reposition half a dozen times and

push with the grapples a time or two before winning.

IslandTractor - I followed your thread before. What is the largest stump you've managed to dig up to date? I'm looking at a new tractor in the future and I could get a small CUT and a Mini-Ex or a larger tractor with basically a BH90x. Wedge