Coyote machine

Super Member

- Joined

- May 4, 2009

- Messages

- 7,663

- Location

- Southern VT

- Tractor

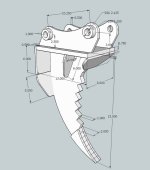

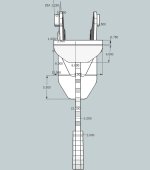

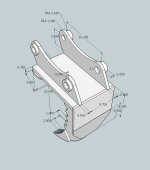

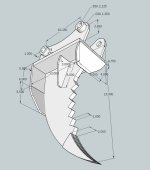

- 22 SANY SY 50U, '10 Kioti DK 40se/hst KL-401 FEL, loaded tires, KB-2485 bhoe, Tuffline TB160 BB, Woods QA forks, MIE Hydraulic bhoe thumb & ripper tooth, Igland 4001 winch, & GR-20 Log Grapple. Woods BBX72" Brush Mower. Diamondplate aluminum canopy

The end tooth is a replaceable tip. I will be mostly dealing with trenching in clay bases soil with a large amount of volcanic rounded rock. So I figured the solid tooth that you and Island Tractor have would get worn and damaged... so a replaceable tooth seemed logical... to me at least. I know that Island Tractor is not fond of it either. I am a bit worried about the weld of that item to shank as all the force will be of those welds.

In post #19 on page 2 I showed a few pics of the adapter and the replaceable tooth

IT and I are both in New England ~ AKA Rock land!