IslandTractor

Super Star Member

- Joined

- Sep 15, 2005

- Messages

- 16,647

- Location

- Prudence Island, RI

- Tractor

- 2007 Kioti DK40se HST, Woods BH

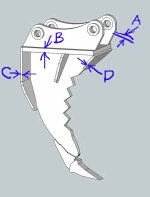

Looks good. Two comments. One is that you don't show any bevel on the cutting edge. I presume that is something you will do. The teeth will be more effective as a serrated blade than just flat faced. Second is that the backplate, which is critical for removing spoils, just looks a little smaller than mine. I have posted photos of my ripper you can compare to. I'll try to remember to measure mine next time I am at the tractor. With my ripper and backplate, I can remove roughly the equivalent of two hand shovelfuls of dirt at a time. Very useful for trenching or even digging out a big stump.

I'd also suggest that you consider getting a main bucket pin that is maybe 2" longer than standard and then taper the first 1.75" or so as that will help you line up the mount with the dipper.

I'd also suggest that you consider getting a main bucket pin that is maybe 2" longer than standard and then taper the first 1.75" or so as that will help you line up the mount with the dipper.