mjncad

Super Member

Don't feel so bad about your project taking longer than expected. Some (most) of my projects move at a glacial pace if I'm lucky.

I like how you did the curves on metal on doors for windows .. nice job. I couldnt do that .

Here's the weatherstripping I used in the picture above:

Shop Frost King 1/4" x 3/8" x 17' Grey, D-Section EPDM Rubber Weatherstrip Tape at Lowes.com

It's purpose is to perform as a gasket between bolted-together sections. I did get some really nice door gaskets from McM/C as you suggested earlier. It is really nice material. It has metal embedded in the rubber that grabs the flange and a hollow "D" profile that will really take care of any gaps.

Don't sell yourself short. I have some experience with metal but never attempted anything of this magnitude before.

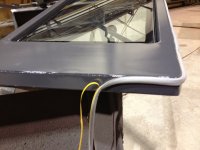

Here are a couple pictures of the door weatherstripping from McMaster. It is very pliable and will take on whatever amount of compressing required to to seal the gaps at the doors.

View attachment 296041

View attachment 296042

Here's the weatherstripping I used in the picture above:

Shop Frost King 1/4" x 3/8" x 17' Grey, D-Section EPDM Rubber Weatherstrip Tape at Lowes.com

It's purpose is to perform as a gasket between bolted-together sections. I did get some really nice door gaskets from McM/C as you suggested earlier. It is really nice material. It has metal embedded in the rubber that grabs the flange and a hollow "D" profile that will really take care of any gaps.

Don't sell yourself short. I have some experience with metal but never attempted anything of this magnitude before.

Here are a couple pictures of the door weatherstripping from McMaster. It is very pliable and will take on whatever amount of compressing required to to seal the gaps at the doors.

View attachment 296041

View attachment 296042

Oops, I forgot I already suggested McMaster-Carr. That "D" shaped material you got from Lowe's looks pretty good. The McMaster-Carr weatherstipping you got was exactly the style I was thinking about for your build.

How cold is the shop that your cab is in? Maybe the temperature is too low for normal curing times.

When siliconing, try running a length of masking tape each side before applying silicone - then run finger around, remove tape & you get a perfect, uniform edge, looks great & easy to do in kitchens & bathrooms, maybe not so much on a tractor!!