mjncad

Super Member

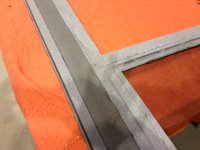

When siliconing, try running a length of masking tape each side before applying silicone - then run finger around, remove tape & you get a perfect, uniform edge, looks great & easy to do in kitchens & bathrooms, maybe not so much on a tractor!!

Great idea, I'll have to remember that one. I hate caulking as I make a mess that rivals my use of a grease gun. My brother-in-law is an artist with a caulking gun. I've never seen anyone who can run a perfect bead with minimal tooling and mess like he can.

For silicone and other caulks a DIY trick that I read and tried is to use an ice cube to push/spread the caulking.

It works!

Sure better than wetting the finger tip.

That's a new one to me.