mjncad

Super Member

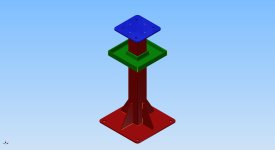

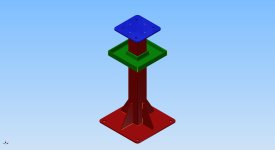

Sometime ago I treated myself to a new 6-1/2" vise as I was tired of using a 55 - 60 year old 3-1/2" vise that was my old-man's. My workbench is too flimsy to handle this vise, so I built a pedestal for it. I could have bought one from Wilton; but they wanted well over $400 just for a simple pedestal that is made from thinner materials than what I made mine out of.

The following three images are teasers, and all the pictures can be viewed at: https://picasaweb.google.com/110106108324823291002/VisePedestal02#

The following three images are teasers, and all the pictures can be viewed at: https://picasaweb.google.com/110106108324823291002/VisePedestal02#