Here is where I am. How do I separate the auger from the gear box???

Sent from my iPhone using TractorByNet

================================================================================

OKKKKK

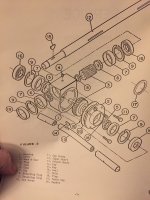

NOW: the shaft is a one piece animal from worm gear back to

the PTO shaft carrier bearing? so that is clear to me now I think.

For some reason the shaft sheared directly behind the worm

gear in side the gear case.

This certainly reeks of Swamp Ape Stink because it takes huge

amount of energy to break a piece of round stock normally.

let alone friction welding a shaft assembly.

Its entirely possible to have sheared it off when you backed into the pile

if it was frozen solid as the augers would have stalled at the same time

due to the spur gear being stopped dead and the shear bolts not breaking.

The shear pins are your first line of defense with a snow caster and the only

thing that protects a worm gear driven snow caster like your and mine and

any walk behind unit.

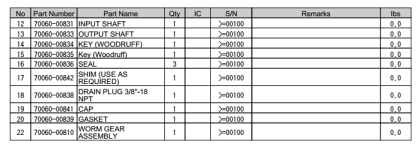

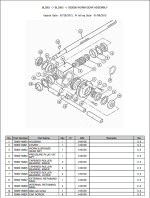

The entire shaft has to be removed and then replaced meaning the worm to spur gear gearbox has

to be split and the entire shaft replaced.

new seals installed as well.

I guess you will have to decide if its worth fooling with and dealing with it.

I cringe every time I use mine as the worm drive gearbox is very expensive for an

RAD excuse for a snow caster.

The greater majority of the newer snow casters do not have the worm gear

driven cross augers that I know of.

Even a new four footer would work well for your cub.

The allied farm king snow casters always seemed pretty reasonable.

Send Ken Sweet a PM through the forum here and ask if he has any snow blowers

left to sell as he was selling them out to get them out of his inventory as he has

much better weather in Kentucky than most.

He ships right from his warehouses too.

I am not trying to spend your money but you have pig in poke there. I am sorry this happened to you.