fitterski

Gold Member

- Joined

- Oct 20, 2016

- Messages

- 377

- Location

- Nouvelle, QC

- Tractor

- 1987 Cat-426, 1991 Deutz-Dx-6.05, 2019 Husqvarna 2xHP

RQV governs the engine to where you set the throttle. In other word if you set the throttle for the engine to run at 1500 rpm the governor will attempt to keep the engine rpms at that speed within the limits of engine power. The RSV type governor which is what you have on the automotive motor governs idle and full throttle. In between is governed by the throttle pedal in the cab of the vehicle. So if your blowing snow at 1500 rpm and run into a heavier load the motor will slow down because the governor isn't reacting to the load. Conversely if the load lightens the engine rpms will increase. Whereas with an RQV style governor the injection pump will automatically adjust the throttle to try to keep the engine at 1500 rpm. Believe me you will be a lot happier with an RQV style governor.

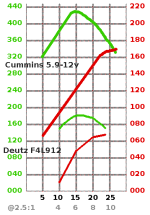

I suppose the RSV type became necessary with the onset of digital controls as protection against the wire monkey. There are 'fuel plate' kits for raising the max rpm but they're another story. On my Perkins and the Deutz engines these stops are just screws, as they have been for almost two centuries on every form of engine. That RQV type could be useful but here again I will possibly want to use the fan itself as rpm reference. It's something to keep in mind for sure, seeing that with this Cummins I might just have enough power on tap not to have to use all of it all the time.