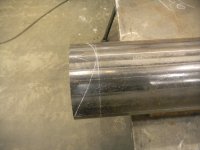

I used a hole saw to cut notches in tubing that fit perfectly. But the HF notcher clamp didn't perform well for me and I found a basic vice on my drill press better. But you must have the room and the ability to level the tubing while cutting it. Can't be in a hurry.

A man skilled with a cutting torch is the fastest I've seen. But I don't own one and I'm certainly not skilled with one.

Good luck!

A man skilled with a cutting torch is the fastest I've seen. But I don't own one and I'm certainly not skilled with one.

Good luck!