ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

Many of us with many years of flail mower ownership and knowledge

regarding flail mowers their operation and knife type have tried to help you with this.

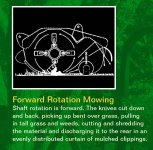

This specific flail mower rotors rotation being counterclockwise as you have stated

will affect the quality of cut with the one piece scoop blades which I have gone

into extensive detail on many occasions for owners of flail mowers with the scoop

one piece knives.

the scoop knives counterclockwise rotation has the cutting edge coming behind the material

the flail mower user wishes to cut down and the the material will flood the front of the flail

mowers shroud when the portion of it that is cut is carried over the flail mower rotor and

will not be recut.

scoop knives do not recut material they cut and carry it over the flail mower rotor and anything

left in its path is dimply carried over again and dropped on the ground.

If you visit the Hiniker home page and look at the flail shredders with the scoop knive option it explains it very well.

The number of times a plot or area is cut will also affect how the flail mower with the scoop

knive will cut the grass or brush and the quality of finish.

==============================================================================

But I thought you said my rotor was not rotating the same direction as the tractor tires?

I thought you also indicated that my problem might be my lack of knowledge in setting up the mower??

So what is your solution to my problem now??

Oh, and you might also acknowledge Arc weld's comments as having some merit. Or maybe not....