zing

Platinum Member

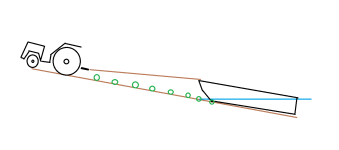

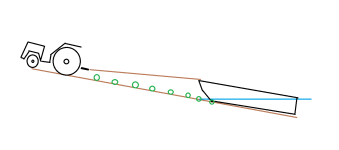

Because of my confusing description, I decided to draw a crappy picture. If you try to drag the boat up greased planks it is going to slide off the sides, just use log rollers to defeat friction. You still need to float the stern and get as much water to drain out as possible so you don't damage the boat with all of that extra weight, but once you lighten it up it should roll quite nicely.

Last edited: