OzarksHermit

New member

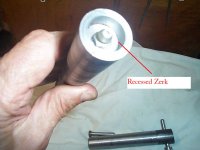

No need to drill both ends (you can't anyway, because the thru bolt hole will interrupt the flow on that end), you only need to drill about 2 1/4" to get past the first bushing inside the Kubota pieces. From there it opens up some, & the grease will surround the pin & flow to the other side. Of course you need to cross drill to wherever you stop to give a path out for the grease. The Kubota pin is drilled about half way, but that's not really necessary. You're also gonna want to counterbore enough to recess the fitting big enough to fit a grease coupler.

I decided not to bush the end I turned down, because the fit was not much different than on my low hour backhoe bucket, and that piece doesn't even have a boss to hold the pin, just a hole in the plate. The ripper has much more robust pin bosses. And since the pin is the correct size for the machine, nothing orange is subject to wear. Another option is to grind off the bosses on the ripper & weld on some with the 25mm ID.

For those not wanting to mess with machining pins, you might try ordering the Kubota pins that are next up on the dipper stick. They are the correct length, are retained by a thru bolt like the ripper, & already drilled for grease. Then you could either live with the slightly sloppy fit on the ripper (I suspect the guy that wrote the review on the DR website did just that), shim the bosses with some .010" brass, or tighten the fit of the bosses by deforming or replacing them. Remember the pin does not rotate in the ripper tooth. Not sure of the price of the Kubota pins though.

Thanks . .

Previous to your message I pulled one of the pins on the Kubota, and discovered what you explained about the grease passage. Based on what you said, I will re-evaluate using a bushing. You are right, it shouldn't make that much difference.

I ordered it yesterday, $124.99 plus $25 shipping - not a bad price.

Ken