I ordered this ripper last week, & thanks to ryan08's timely information, I was able to add the pins to my order after a credit card glitch delayed my shipment.

It arrived today, & I think I was able to figure this issue out. I too was unable to get the DR pins to pass thru the Kubota pieces, so I compared the diameter of the Kubota bucket pin to the diameter of the DR pin. Turns out the DR pin is just a couple thousandths over 1", but the Kubota pin measured about .978.

Since .984 = 25mm, I think the obvious answer is that the Kubota pieces are metric, & the DR pins (& mounting holes) are SAE.

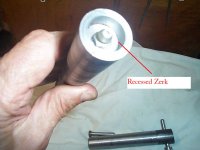

Close enough for me though, I chucked the pins up in my lathe, & whittled about .010 off to get the diameter to about .980". I left the first 1" untouched to keep the pin tight in one side of the ripper. Not sure if I will try to come up with something to bush the other hole to the new dimension, or add some .010 shim stock when mounting it. Will probably just use it without anything unless I plan on using it for a long project. Or since the pin is bolted to the ripper & rotates in the Kubota pieces, it might make sense to just deform the holes in the ripper slightly on that side.

Also worth noting is that the machine that this was designed for has about the same breakout force as does the backhoe on my

BX24, so I don't think it is underbuilt for this application. Seems pretty sturdy.