OK a little more progress has happened and will try to keep this thread updated. First picture, there are several changes. First the frame is standing on end and you can see the trailer tongue welded into place. You can also see the struts that the spindles will be welded onto. At the top of them is where I welded the "axle" for the pivot point for the trailer tongue, when in dump mode.

I racked my brain over and over again on different ways to accomplish the "dump" feature and I finally decided on the K.I.S.S. method (keep it simple stupid). The trailer bed simply pivots on the tires themselves, with the tongue rotating right above the spindles. I also canned the idea of using the quad's suspension. It just wasn't going to be feasible. I love a trailer with a soft enough suspension to not bounce all over, but if I kept going like I was, it would outweigh my quad. LOL

I think I said earlier my sticks of tubing I bought were 31ft, I was wrong, they were 21. The used stuff is 31.

That said, I so efficiently used up my 2 sticks of the 1 3/8 tubing, I had to splice 2 pieces together to make a piece long enough for the tongue "axle". On that topic I also racked my brain a bit and came up with the existing plan. I made a piece long enough to got from strut to strut, and made the 1 7/8 tubing (the black pipe in the picture) several inches shorter. This gave me enough room to slide the tongue piece (the horizontal part of the "T" in the picture) from side to side and allow me to weld the "axle" onto the frame.

Here's a better angle I think.

Here's a close up of my weld. Don't be too critical. It usually isn't pretty, but I tend to go overboard. One thing I do do, is make sure to get penetration. A couple times I burned all the way through and had to patch it up. I can see the puddle pretty well most of the time and it is usually on the verge of burinig through.

On the ends, where I left the extra play, I did not want the tongue to slide back and forth, so I cut a narrow section of the 1 7/8" tubing and cut it in half, like lemon slices. I placed one of the halves on each end of the tongue axle up against the rotating part of the tongue. I then tacked it in place to the axle to keep everything centered. Kinda hard to tell in that shot.

Here's the frame sitting as it will when the tires are on. You can see the tongue sticking out the other end. It extends 3 feet from the main frame. You will also note I added the upper horizontal braces to the uprights. The only thing left on the upper frame is 1/2" square tubing that will be added as bracing for the sheet metal bed, and also to build the end door frames, also out if 1/2" sq tubing.

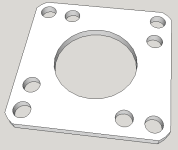

Here's the latch for the trailer in tow position. This will keep the bed down. The screw will go through, but I am not concerned with it at this moment because the hole need to be opened up a bit anyway for the latch pin I will use.

Here you can see the tongue with the latch welded on it. It's also a good shot of the struts for the spindles. The struts are 6" long for reference. I will add fore and aft bracing to that center strut. I also need to add side bracing to the tongue. Not 100% sure it's needed, but I do not want anything getting tweaked if I take it off road. For that I will use some 1x2 .090 tubing that I have laying around.

OK that's it for now. I will finish up the last few details until the hubs and spindles arrive and then I can complete the welding, and move on to sanding and painting. I am thinking orange on the frame, to go with my Husqvarna tractor, and leave the sheet metal bare galvanized. I might paint it with some sort of silver paint. but not sure.