Catman8

Gold Member

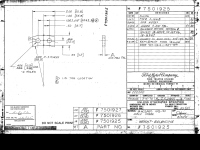

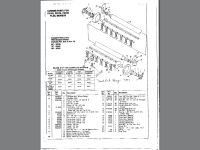

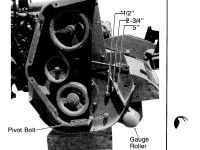

The manual tells you how thick, and has a pretty good picture to estimate size, so I'd still start there. You won't be an exact match, but presumably much closer than no weights at all..

Yep, cut a piece of steel 1-15/32" thick and start from that point. From the photo the width and height should be obvious. Thanks for the idea.