jodebg

Platinum Member

Thanks for the clarification. There's no .253 square tubing for the 2x4 forks?

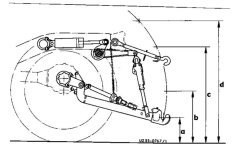

One important question remains. Where is the ideal location for welding the lower link brackets and mounting to top link.

I know you had mentioned before that this will assist in maximizing lift capacity.

So, what is the theory behind where the links should mount and what the links should

look like when connected to this frame, when the frame is sitting on the ground?

One important question remains. Where is the ideal location for welding the lower link brackets and mounting to top link.

I know you had mentioned before that this will assist in maximizing lift capacity.

So, what is the theory behind where the links should mount and what the links should

look like when connected to this frame, when the frame is sitting on the ground?

5x3x1/2 has an ID of 2x4. If you used 2x4 tube for the forks, they could be inserted and removed same as the plans.

Last edited: