brain55

Veteran Member

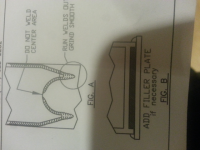

I couldn't decide which forum to post this in. I finally decided it was more of a welding job than anything for me. Anyway, I ordered an Amulet thumb for a customer's Caterpillar 305 CR excavator Friday. They have to build it and ship it to me. I expect to see it the coming Friday and put it on Saturday. I will definitely post pictures before, after, and during. It should be a fun job. The hydraulics are already on the machine so all I really need to do is weld the brackets for the cylinder and thumb, mount them, and make the hoses to the cylinder.

I quoted my customer $3000 for the job.

Brian.

I quoted my customer $3000 for the job.

Brian.