weldermike

Platinum Member

- Joined

- Jun 18, 2011

- Messages

- 599

- Tractor

- kubota L4400

someone told me it would be impossible to weld 1/4 with my 180 amp syncrowave.

Shield Arc said:Hook up a bottle of helium, and you'll be turning that Syncrowave down, way down!

Woodsmith, after reading all the suggestions from the other members and I agree with most of them, here is something different and save you a few bucks. The cleaning is the most important overall, but instead of buying degreasers, solvents and such, just use vinegar. You say you used a s/s pad to clean with, thats good as long as you only use it on aluminum and always use a clean side or you're just rubbing contaminats back into the metal. After the pad, spray or brush it with vinegar, that will nutrilize the metal. Without a spool gun its hard to use the smaller size wire, really need .030 but to help absorb the heat from the bigger wire and give you more metal to work with get some aluminum rod, 1/8,5/32 and lay it between the tubes where you are going to weld, be sure to clean the rod too. I differ with a couple quotes here, you can make mig look as good as tig. I have been welding for over 40yrs and although tig is good, mig is faster, I hope this helps in some manner.

Your a lucky man, I would love to get my hands on a dynasty, I live in a world of transformer machines, at work and at home. Soon enough maybepost some pics with that baby!

With the attitude of these kids now a days, I hate to see where this country is going to be in 25 to 30-years!

Cheers, I was keeping to the clean side of the SS pad but the vinegar is a good tip, I'll try that.

I got my Durafix rods today.

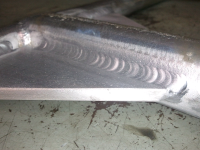

First go with one.

Looks nice like that, though the horrible bits around it are some of the failed MIG attempts from last time.

On some of the videos I saw the surfaces being 'tinned' first and the SS brush used to brush the braze into the surface. I tried that too and now have a brush that is caked in braze!So much for it not sticking to the SS!

Gotta get another brush!:thumbsup:

Shield Arc said:With the attitude of these kids now a days, I hate to see where this country is going to be in 25 to 30-years!

You seen my thread over there, where I had to run that kid off for not showing up, and when he did he was late. I guess free one on one welding lesson wasn't worth getting out of bed for. :confused3:

Heres what a dynasty 200 can do with a hack like me.

This is 1/4" 6061 plate, outside corner fillet. Machine settings: 190A, 70% balance, 129Hz with 1/16" tungsten. (I know, but I was too lazy to put a bigger one in).

View attachment 285982

And these is with 1/8" 3003 plate. One flat weld with no gap and the other Tee joint. Machine set at 100A, 70% bal, and 129 Hz, same tungsten. View attachment 285983View attachment 285984

I wasnt real steady with the flat, but I had my thinner gloves on and it was getting a tad hot and I didnt feel like stopping once I started:banghead:

Again, I dont do this everyday. All total I have maybe 10-15 hours of Tig aluminum time. I gotta give all the credit to the machine I think. And my apologizes for the crummy pics. A camera phone is all I got.

Hey now. I am probabally what you guys would call "one of these kids now a days":laughing:

I think I could probabally say something like " Its a wonder anything ever got done in this country with you old farts":laughing:

If you get a chance try some ceriated (orange) tungsten. I've got to the point now that is all I use, no matter stainless steel, aluminum, or mild steel.