California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 16,726

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

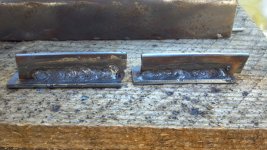

My welding and fabrication needs are minimal - generally an occasional farm equipment repair. I bought Harbor Freight's portable band saw. It should be around $70 using a 20% coupon. So far this meets all of my cutting needs and does an excellent quick job.I can see that I am really under-equipped to deal with other aspects of fabrication using heavier metal--specifically cutting.

Like anything from HF, if you are a tradesman and would use this daily, then the Milwaukee that this is a cheap copy of would be preferable.