plowhog

Elite Member

- Joined

- Dec 8, 2015

- Messages

- 4,048

- Location

- North. NV, North. CA

- Tractor

- Massey 1710 / 1758, Ventrac 4500Y / TD9

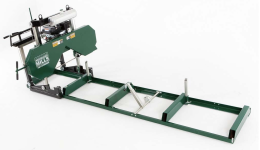

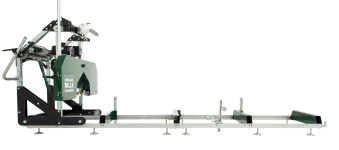

A deciding reason for me was an earlier purchase of a Woodland Mills wood chipper. It works well, was pretty easy to assemble, has not broken down, and was delivered when they said it would be. Choosing Woodland Mills for a chipper was a solid choice-- and I figured the sawmill would probably be similar. It was.I went with Woodland Mills for several reasons.

btw check out Youtube videos "sawing with Sandy" which are excellent. He has a Woodland Mills sawmill. I've watched a number of them.