California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 16,748

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

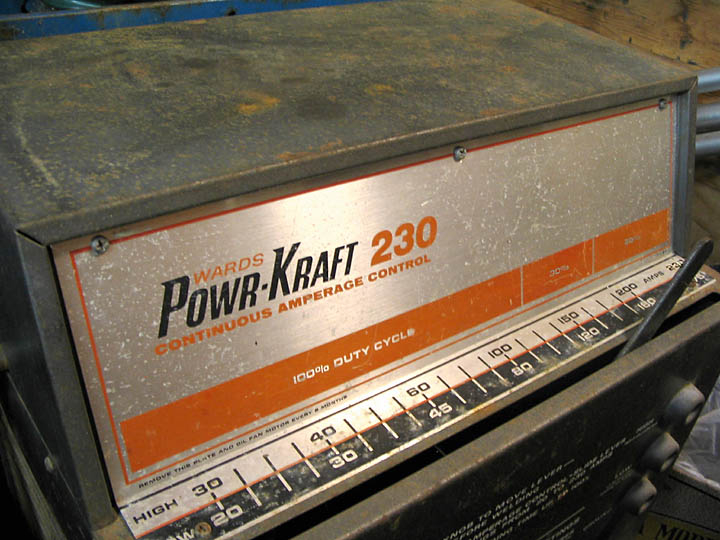

re the heavy Tombstone welder, my $50 Wards PowrKraft AC230 is similar capacity, and weight. It's a beast. 3/8 2011 rod takes about half throttle.

Prior owner adapted a bottle truck to make it portable. Current is varied by a lever that pulls a slug in/out of the transformer core. And the cables are removable for storage. They attach with tapered brass plugs.

I've done some good work with this for example a trailer hitch added to my box blade. My first project was to repair where a pin tore out of an old garage door hinge.

But I've bought several smaller welders since. A dual voltage small flux-core welder is more convenient. I very seldom drag out this big guy, any more.

Prior owner adapted a bottle truck to make it portable. Current is varied by a lever that pulls a slug in/out of the transformer core. And the cables are removable for storage. They attach with tapered brass plugs.

I've done some good work with this for example a trailer hitch added to my box blade. My first project was to repair where a pin tore out of an old garage door hinge.

But I've bought several smaller welders since. A dual voltage small flux-core welder is more convenient. I very seldom drag out this big guy, any more.