daugen

Epic Contributor

good eyes Aaron. :thumbsup:

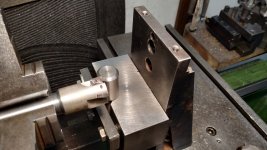

Cutting a radius on the corners and then a round over on the sides would make it nicer. Here’s a trick I use for cutting a perfect radius quickly. For one that small I’d just cut and sand it but for bigger ones I like to make a template to use a flush trim bit with. View attachment 648611

yeah. That happened and the round over will also happen, just never got to it yet. Work got in the way.

yeah. That happened and the round over will also happen, just never got to it yet. Work got in the way.Nice lamination. Hopefully you can disassemble the verticals from the base and run a round over bit with a router on the non mating edges of all the pieces.View attachment 648743yeah. That happened and the round over will also happen, just never got to it yet. Work got in the way.

Great day today... besides getting my propane heater finally working in my shop (its own thread) I also unloaded and placed my new 8in jointer in my shop. Time to read the manual then turn it on and make some chips.

View attachment 649239

Thanks... surplus sale... some scratches and nicks, pretty much new. A heck of a deal. Projects... yes, too many to count... a bookcase, a shoji screen room divider, a Murphy bed for our closet/extra bed space. Figured I better make sure I am outfitted before retirement. Pretty sure there won't be big tool purchases on a fixed income unless my tools are generating some.What a beauty ! Any projects planned??

Thanks... surplus sale... some scratches and nicks, pretty much new. A heck of a deal. Projects... yes, too many to count... a bookcase, a shoji screen room divider, a Murphy bed for our closet/extra bed space. Figured I better make sure I am outfitted before retirement. Pretty sure there won't be big tool purchases on a fixed income unless my tools are generating some.

My 6in jointer is now on the block. Hard to sell online these days due to the lock down. Running out of room!

Was thinking the same... 'hey I might use it... who am I kidding?'I had a grizzly 6” before I bought my Powermatic 8”. I hung onto the grizzly for a while thinking there might be some use for it. I finally sold it and haven’t missed it.

I've had my 8" Rockwell jointer since the early 80's and it's amazing how much more useful an 8" is over a 6". It seems most buy the 6" first, and then learn it's a mistake to do so, myself included.My 6in jointer is now on the block. Hard to sell online these days due to the lock down. Running out of room!

I've had my 8" Rockwell jointer since the early 80's and it's amazing how much more useful an 8" is over a 6". It seems most buy the 6" first, and then learn it's a mistake to do so, myself included.

SR