What I'm thinking is, those little 1HP/6gal "silent" import compressors may not put out enough air for a shop, may not be capable of continuous duty, may not last as long as a good quality one, etc., but...

At <$150 each, I could buy 5 of them, plumb them together along with my 26 gal craftsman acting as a storage tank, and I'd have:

5HP

56gal

15.5CFM @ 90PSI

125 PSI max

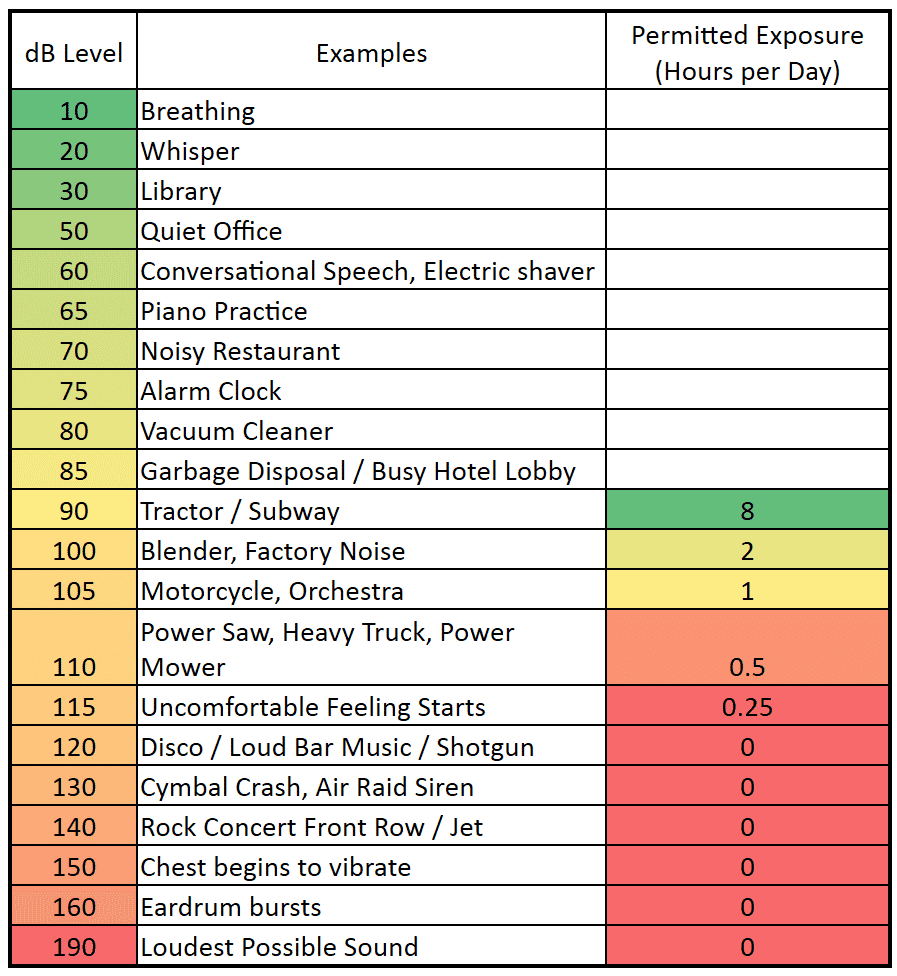

51db (whisper quiet)

... all For $750.

I could connect an analog pressure sensor to a little programmable control board like an Arduino, which would track the run time of each compressor and when the pressure drops below, say 120PSI, it could switch on a single compressor, whoever has the lowest hours. And if it drops below 115PSI, it can switch on a 2nd compressor, the next-lowest-hours compressor, and so on in cascading fashion until all 5 compressors are running in response to a large air demand. This way none of the compressors has to run continuously and as long as air demand is minimal (which is usually), the run time will be divided among 5 compressors, theoretically extending their lifespan by up to 5X. There is the added benefits of having FIVE levels of redundant backup, being able to easily detach a part of your air system and take it on the road, and if a compressor fails you just replace it for $150 and leave the tank connected to your system, so if ever you do experience a failure it's not a total loss; your volume grows with each failure.

Compare that to a

quincy such as this:

$1,399

5HP

60Gal

15.4CFM @ 90 PSI

175PSI max

75db (super loud)

Single point failure if the compressor goes out

The only area I see the Quincy winning in, is max PSI, and I never use more than 100 PSI, so I don't see the justification in paying the extra $650.

(oh yeah, and 4 gal more storage)