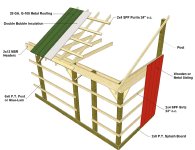

well the random spacing comes with haveing 2- 12' door openings on the eve side so the first spacing is 5' then 12.6' then 3' then 12.6' then 8.6' then 8.6' oc. So i guess on the 5', 3', and the 2- 8.6' spacing i could use 2x4's on edge with that ledger board. Would that be enough strength for the roof?

I assume that the truss designer is aware the your spacing plan?

The truss between the 12'6" bay and the 8'6" bay will be carrying more weight then any other one.