It's interesting how many different ideas on how hydraulic systems work there are.

EricTheOracle said:

At low volume, a given ram will not move under a given load because the relief opens before enough volume of fluid can develop to overcome the load.

Not true at all. Volume (GPM = flow) does not matter. The lifting capability of the ram, and the functionality of the relief are governed solely by the pressure. But the lower the flow, the slower it will be. To have the relief open, the set pressure of the relief has to be met... if it's capable of getting there, it's capable of moving the load.

This is one of the most basic concepts of physics.

A .05GPM source of 3000PSI will

lift the same load with the same cylinder as a 30GPM source at 3000PSI. It will just take MUCH longer. This is pretty simple, and compares via the law of the conservation of energy of RPM vs torque, volts vs amps, etc.

A certain input RPM does not guarantee the pump will be able to build that pressure though, depending on the pump design... but for our purposes...

EricTheOracle said:

That said, 94BULLITT, where did the 14.9hp spec come from? If true, I should have maximum lift at idle, but I don't. I do not doubt your sincerity, but that number cannot be right. If my tractor only needs 14.9 horsepower to generate maximum pressure and maximum flow in an open center system under maximum load is really true, then 25hp subcompact tractors should have monster lift specs, and I and everybody else have been taken.

Pump GPM is proportionate to input RPM, it won't produce the rated flow at a lower RPM than designed. At X GPM and Y PSI, you can find a specific horsepower number required for the input to maintain that output.

A 1/2HP 12vdc hydraulic pump is capable of lifting the same thing as your tractor. It will just take much longer.

Physics come into play. A loader on your example 25hp tractor will flip the tractor over before it lifts 4000 lbs, so it is designed to lift what it can lift efficiently, and not for the maximum lift.

With the engine revved up, the loader maxed, the engine stays revving and the hydro goes to relief. The HST, pump can stall the engine when under a load and combos of the HST pump and load on the loader can and does stall the engine even with anti-stall switched on (a feature, I've never puzzled out what it tries to do).

The HST is a variable displacement pump type, there is not a relief that regulates pressure like the pump for the loader/3 point/remotes/etc... at least not in the circuit with the motor/pump, and at least not before it consumes all available power. That's why it can stall the engine. Don't think of it as a simple open center hydraulic system like used for the loader, where you could direct 100% of the flow through a hydraulic motor, lock it up and have the pressure hit the relief and everything goes on as planned Think of it more as a closed center pump connected directly to a motor - the input to the pump is directly the output of the motor and vice versa. Lock up the motor and the pump will stop (unless something gives first!)

The working HP of the system does not mean it cannot produce a load on the engine greater than that and stall the engine. The HST can and will take up 100% of the power the engine puts out.

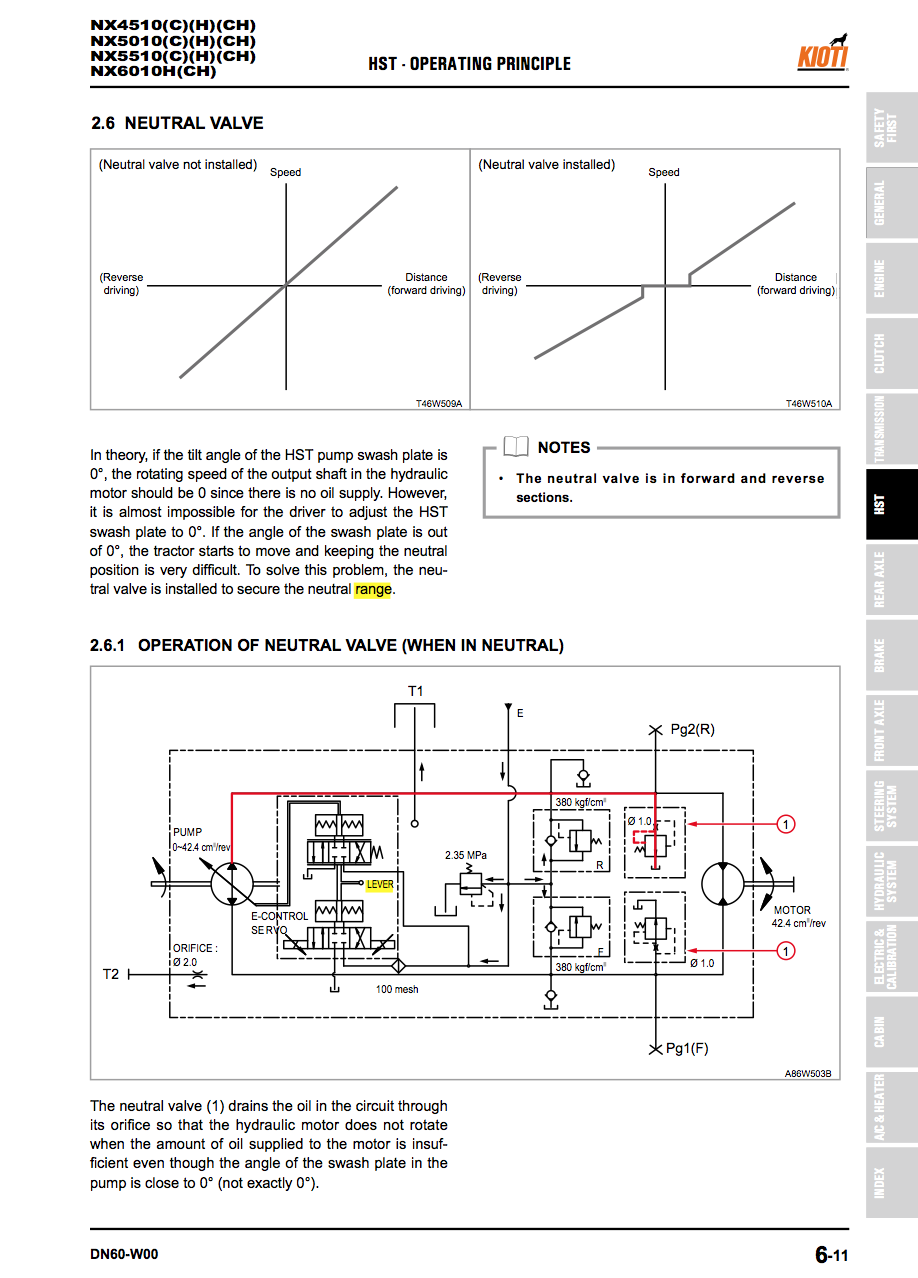

The control for a Kubota or Kioti HST is the same - the swash plates, whether that is done mechanically or electronically to accomplish the goal and features, it doesn't much matter.