Ivan49

Gold Member

If you put that pump on a gear box and if it is geared right you can run your tractor at a lower RPM and still get 540 RPM. What GPM pump do you plan on using

I don't know yet, I have not selected all my actuator. When I will know I will add the total of the actuator that run in the same time and

choose accordingly. Ex: at the same time -chainsaw motor 20 gpm + splitting log convoyer 15 gpm= 35 gpm continuous

I intend to use two hydraulic pump. I saw someone using 2 pumps. one for all the cylinders and the other one for all the motors.

Do you think there is a reason to divide the actuator on 2 circuits in such way?

I have a question about the splitting cylinder. Do you know what size of cylinder should I get

to split mainly 16 inch, but sometime maybe 18 or 20 inch? What should the stroke length be? the length of the log + 4, 5, or 6 inch or more?

I don't know yet, I have not selected all my actuator. When I will know I will add the total of the actuator that run in the same time and

choose accordingly. Ex: at the same time -chainsaw motor 20 gpm + splitting log convoyer 15 gpm= 35 gpm continuous

I intend to use two hydraulic pump. I saw someone using 2 pumps. one for all the cylinders and the other one for all the motors.

Do you think there is a reason to divide the actuator on 2 circuits in such way?

I have a question about the splitting cylinder. Do you know what size of cylinder should I get

to split mainly 16 inch, but sometime maybe 18 or 20 inch? What should the stroke length be? the length of the log + 4, 5, or 6 inch or more?

I have mainly maple, ash and beech. I would like to process 200 face cord per year.

My budget is 7000 Canadian dollar. I need to purchase almost everything.

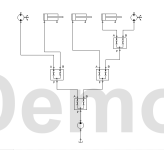

I want to have a log table infeed, something like this:

View attachment 590901

View attachment 590904

Theses models are driving by the PTO of the tractor.

Why should they have gearboxes? It does not make sense to me. They size the hydraulic pump accordingly. There is no need for mechanical gearing down since the hydraulic pump's displacement will be sized to match the load and flowIf you notice those have a PTO shaft on them. That means the pump is left on the processor l the time. Do some research on them and see but I would not be surprised if they don't have a gear box running that pump. That way you can use lower RPM's on your tractor. E mail the company or talk to a dealer that is the best way to get info to build what you want and then you can use ideas from several to make yours

Why should they have gearboxes? It does not make sense to me. They size the hydraulic pump accordingly. There is no need for mechanical gearing down since the hydraulic pump's displacement will be sized to match the load and flow

Just use a higher gpm pump and turn it slower to accomplish the flow you need.

I have a new question:

Do you think that the valve of the hydraulic chainsaw need a motor spool (work ports A and B connected when valve in neutral) ?

Or there is not enough inertia to have this kind a valve?

Thanks