Somo flow controls have restricted flow in one direction and full flow in the other direction.

He probably does not have much pressure on the saw push cyl.

The saw max GPM input is 13.7 GPM continuous, and `5.7 intermittent.

Do you mean my saw motor input flow? if so, F11-010 parker motor have 25.6 GPM continuous max flow, and 28,5 GPM intermittent..

J.J..don´t you help me with one thing?

tomorrow I need to set up splitter reliefs correctly, and don´t have sure how to do that, since i have hi low pressures to set up, and a sensor that don´t let me extend cylinder to max..you think i can do it this way?:

If i disable this sensor, the cylinder will extend to the max and is going to put all shop electricall installation down (trust me, it happens a lot

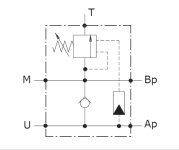

)..so if i open the two reliefs that my Walvoil unloading valve have (one for HI and another for LOW pressure) all the way counterclockwise, when the cylinder extends to max the valve should bypass flow to tank since the pressure is set at the minimum, wright?..

then, think gradually ajust pressure UP in both LOW and HI pressure relief valves at the preset numbers (about 1200 PSI) should mean that my two pumps are going to bypass to tank at this pressure..and then if I set gradually up only my HI pressure relief valve, means that only this pump will flow to the cylinder above this preset pressure since the low pump is already adjusted and bypassing to tank at 1200 PSI..am I wright?..ajusting the second pump to about 2800 PSI, means that at this pressure my second pump will bypass oil to tank too, while my first pump is still bypassing it..all this have to be done with cylinder extend to the max..it´s should stay there, bypassing oil to tank, and not shut down shop electricalls, or damage a pump, or burn motor, or whatever..

Is this the correct way to set up this reliefs?..i have a 6000 PSi gauge connected to splitter main block valve, so it should be able to measure this easly..