Wild Bill the 2nd

Gold Member

We got a little more work done this evening.

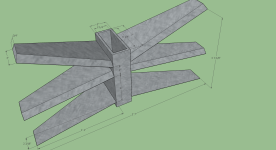

Cut down the lawn tractor frames and removed the front axles.

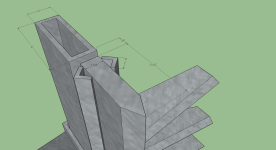

Welded the supports that will hold the motors.

So the tractor engines, frames and all, will be installed in the processor. They will be welded to the pieces of angle running right to left about a foot up from the bottom frame members.

Cut down the lawn tractor frames and removed the front axles.

Welded the supports that will hold the motors.

So the tractor engines, frames and all, will be installed in the processor. They will be welded to the pieces of angle running right to left about a foot up from the bottom frame members.