GuglioLS

Veteran Member

- Joined

- Feb 13, 2005

- Messages

- 1,155

- Location

- Edgewood, NM USA

- Tractor

- Jinma 354, 1953 Ford NAA Golden Jubilee, Komatsu Bulldozer

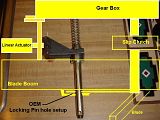

Here is a side view of the wedge showing a little more detail.

This is the theory of how it operates-

Lets say I want to rotate the blade - push a switch to activate the linear actuator, wedge lifts pin, rotate blade, push another switch, retract the wedge, if the pin in not exactly lined up, rotate blade a little then the pin will instantly index then lock into the hole by a spring.

Larry

This is the theory of how it operates-

Lets say I want to rotate the blade - push a switch to activate the linear actuator, wedge lifts pin, rotate blade, push another switch, retract the wedge, if the pin in not exactly lined up, rotate blade a little then the pin will instantly index then lock into the hole by a spring.

Larry