You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

X-cord for welder

- Thread starter GeneV

- Start date

- Views: 9265

- Status

- Not open for further replies.

More options

Who Replied?

/ X-cord for welder

#21

workinonit

Elite Member

The circuit breaker is there for 2 reasons. To protect the equipment and the conductors from overcurrent/overload situations. We have had this debate before and I understand that you CAN run a welder on a much smaller conductor but to recommend to others, especially novices, the downsizing of conductors is just irresponsible. Ratings are on equipment for reasons and they should be wired accordingly. A 10 gauge wire on a 50 amp breaker is unsafe, plain and simple. Conductor size and breaker size should be matched. Certainly on a fault the breaker will trip on pretty much any size wire. That's not the case in an over current condition. That's a recipe for a blowout or a fire. I've seen those first hand and I can tell you faults and over current conditions are not very pretty.You would be correct that voltage drop is really the issue on the user end. A short circuit or even overhrat and a 10 wire will trip a 50.

The machine needs the 50 breaker but doesnt really need a 50 wire.

workinonit

Elite Member

Nice cord. Mine is very similar.Nice cord, unraveled fairly easy, straightened out pretty fast. Receptacle end lights up to let you know it's plugged in. Yup, this was a good buy.

Sberry

Platinum Member

I agree about a little and that is the point i am making. There is a big hang up on the wire size at the expense of other relevent and often dangerous practices.

Knowing one thing is different than knowing it well.

Workingonit seems like a fine fellow but this is what i am getting at. The opinion that what this code allows, the fundamental priniciple almost all circuit design is based on is not faulty.

My explanation may not be the best so it might be worth it yo find someone a guy can relate to better to explain it.

But the amateur tells us the proffesionals, all the codes are wrong and dangerous cause he has 5 minutes of study on one line.

Knowing one thing is different than knowing it well.

Workingonit seems like a fine fellow but this is what i am getting at. The opinion that what this code allows, the fundamental priniciple almost all circuit design is based on is not faulty.

My explanation may not be the best so it might be worth it yo find someone a guy can relate to better to explain it.

But the amateur tells us the proffesionals, all the codes are wrong and dangerous cause he has 5 minutes of study on one line.

Sberry

Platinum Member

I got to wonder if this isnt right why they leave it in the code for over 75 years. As i mention,, this focus often actually creates a problem vs preventing it.

Most of the worlds equipment is plugged in to breakers larger than the machine requires, the alarm clock etc. Same for the welder. The AC buzzer sold by the millions has a 12 cord plugs in to a 50 circuit. Changing the circuit wire from 10 to 6 doesnt help much.

As i recall there was a guy qire his welders with 4 to 50 outlets and put 80A breaker on it because,,,, the breaker only protects the wire. This is super faulty and extremely dangerous and a poster case for self education. The learning stopped after hearing that one line.

I know some guys study under that guy,,, someone told me,,, i was always told but he aint a very good teacher.

The instruction manual for decades to a 225 from Lincoln with the code section must have been written by idiots because there is a guy who has "always ben told" knows way more about it than they do.

Most of the worlds equipment is plugged in to breakers larger than the machine requires, the alarm clock etc. Same for the welder. The AC buzzer sold by the millions has a 12 cord plugs in to a 50 circuit. Changing the circuit wire from 10 to 6 doesnt help much.

As i recall there was a guy qire his welders with 4 to 50 outlets and put 80A breaker on it because,,,, the breaker only protects the wire. This is super faulty and extremely dangerous and a poster case for self education. The learning stopped after hearing that one line.

I know some guys study under that guy,,, someone told me,,, i was always told but he aint a very good teacher.

The instruction manual for decades to a 225 from Lincoln with the code section must have been written by idiots because there is a guy who has "always ben told" knows way more about it than they do.

Sberry

Platinum Member

The fact that we can plug a 16 cord in to a 20 outlet kind of explains this. Lots of hard wired equipment wired under this principle as well as the internals of the equipment.

About the only place that is wired full are general outlets with the exception of welders which there is an allowance for.

Millions of AC buzzers wired with 10 cable to 50 fuses for decades by masters under code. Seems a guy might wonder,,,, why, , how can this be safe? Why would they allow this?

About the only place that is wired full are general outlets with the exception of welders which there is an allowance for.

Millions of AC buzzers wired with 10 cable to 50 fuses for decades by masters under code. Seems a guy might wonder,,,, why, , how can this be safe? Why would they allow this?

Sberry

Platinum Member

There are guys know more about this than most people do and do not need to learn any more , the someone told me school of study obviously supercedes years of study but there are others that should know a couple fundamental principles this system is based on.

There is nothing wrong with upsizing a wire a couple 3 bigger than it needs but it doesnt need to be and doesnt add as much to safety ss it might appear at first glance.

Rhere are some common pieces represent this, they are similar to much internal equipment design where the breaker does not provide thermal. Yes it is part of it and on occasion does become active but equipment does not depend on it for thermal overload ,, that comes from applied load or design.

A little like the common power strip. The added protection is not for fault but thermal overload like other thermal resets found elsewhere. The fault protection is still provided by the breaker. Thermal is only one feature a breaker has and really (for this type of discussion) applies to circuits with multiple outlets can be overloaded by the user.

There is nothing wrong with upsizing a wire a couple 3 bigger than it needs but it doesnt need to be and doesnt add as much to safety ss it might appear at first glance.

Rhere are some common pieces represent this, they are similar to much internal equipment design where the breaker does not provide thermal. Yes it is part of it and on occasion does become active but equipment does not depend on it for thermal overload ,, that comes from applied load or design.

A little like the common power strip. The added protection is not for fault but thermal overload like other thermal resets found elsewhere. The fault protection is still provided by the breaker. Thermal is only one feature a breaker has and really (for this type of discussion) applies to circuits with multiple outlets can be overloaded by the user.

Sberry

Platinum Member

Good place to study this is sizing for multiple motors.

jaxs

Elite Member

I see where you are coming from. Another example of common sense and experience proving engineers and popular belief to be wrong is fasteners. Most machines (even electrical devices) have more bolts and screws than neccessary holding them togeather. A mechanic that learned by experience rather than formal training often doesn't waste time replacing more fasteners than required to hold things togeather. The result is higher production,added income and faster disassembly in the future. So yea,engineers and desighners don't always know more than the man on the street.

the old grind

Super Member

- Joined

- Jul 21, 2012

- Messages

- 5,308

- Location

- Mid-Michigan

- Tractor

- NH T-1520 HST, NH TC33DA HST, Case DX26 HST, .Terramite T5C, . NH L785

30A breaker and 6-50 plug on a 12 ga circuit? Show that to an inspector and let him know it's ok for welders. Never mind any safety factor in NEMA specs if you can get away with saving a few bucks on the cost of wire. btw, Voltage drop on long runs is soo over-imagined.

WranglerX

Super Member

Keep in mind NEMA and NFPA specs for welding device circuits are different than for electric driers and stoves and air compressors and such.... And also read up on wiring requirement in manual of welder, just because it has a NEMA 6-50 plug (has become pretty much industry standard plug/receptical) does no mean it requires 50 amp breaker and #6 wire....

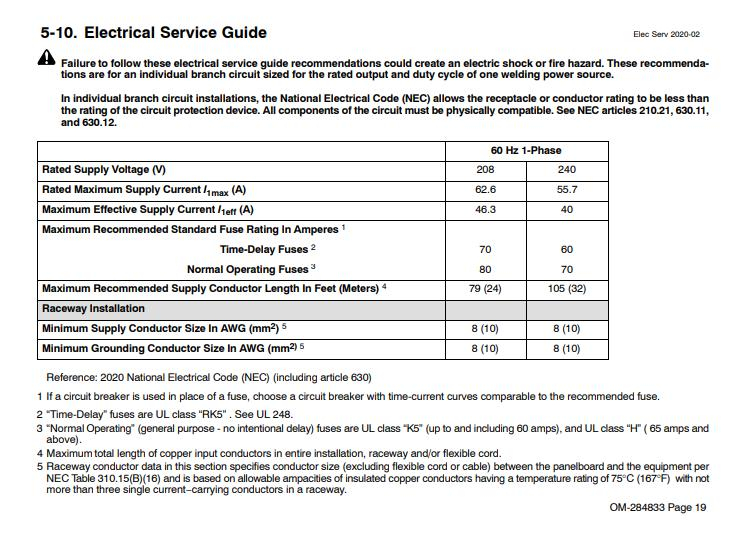

For example Hobart Ironman 240 MIG welder...

For example Hobart Ironman 240 MIG welder...

Sberry

Platinum Member

I am getting at a missing link in the forum where the explanation falls short. This happens on electric forums too. There is a lot of pissing about code compliance but comes up short as to "why".

There are some highly technical answers most over my head but there is and are a couple fundamental aspects of common circuit design often missed. This is similar to paint booth, there is aleays about the third comment on how he pressurize a paint booth which makes it evident he doesnt have any grip on how it works.

The electric is similar in some respect but the fault with it or some of it really not dangerous. Its not going to hurt anything to use a wire cost 4$ a foot instead of 1.

The error with this is that their life will be vastly improved and they will become more handsome un the near future.

There is an argument for future proof and it does have a place but it usually doesnt pay to park 3$ a foot extra just in case, same for the extra conduit in the ground.

Been there, done it, demand often goes down before up and some becomes obsolete.

I run a lot of 1/2 conduit, never once. Never wished i ran 3/4 to a light fixture or service switch cause i needed to add a welder circuit later..

Lots of stuff that is dedicated run another wire or pipe to anyway, every wire doesnt need to run in one pipe.

There are some highly technical answers most over my head but there is and are a couple fundamental aspects of common circuit design often missed. This is similar to paint booth, there is aleays about the third comment on how he pressurize a paint booth which makes it evident he doesnt have any grip on how it works.

The electric is similar in some respect but the fault with it or some of it really not dangerous. Its not going to hurt anything to use a wire cost 4$ a foot instead of 1.

The error with this is that their life will be vastly improved and they will become more handsome un the near future.

There is an argument for future proof and it does have a place but it usually doesnt pay to park 3$ a foot extra just in case, same for the extra conduit in the ground.

Been there, done it, demand often goes down before up and some becomes obsolete.

I run a lot of 1/2 conduit, never once. Never wished i ran 3/4 to a light fixture or service switch cause i needed to add a welder circuit later..

Lots of stuff that is dedicated run another wire or pipe to anyway, every wire doesnt need to run in one pipe.

Sberry

Platinum Member

They alliow 65 ft of 14 on 30 A to 6/50

Sberry

Platinum Member

Not only csn you put 12 on a 30 you can put it on 50

Sberry

Platinum Member

Dale makes a good distinction about the difference in types of circuits. I think the manuals and that chart above is designed for the "qualified" as they say. It kind of assumes the guy reading it will understand what it means.

What it doesnt say clearly is,,,, if you use this minimum wire which you can legal that you need to limit the breaker to 30 but if the wire is larger (not cause the machine needs it but the code requires it) that this machine is allowed on 50A circuits. Because it comes with a 50A they assume the ocpd will be 50 and not 60 or 80.

This is why we dont simply allow larger breakers on smaller outlets, its not to protect the wire from thermal but to limit short circuit.

What it doesnt say clearly is,,,, if you use this minimum wire which you can legal that you need to limit the breaker to 30 but if the wire is larger (not cause the machine needs it but the code requires it) that this machine is allowed on 50A circuits. Because it comes with a 50A they assume the ocpd will be 50 and not 60 or 80.

This is why we dont simply allow larger breakers on smaller outlets, its not to protect the wire from thermal but to limit short circuit.

Sberry

Platinum Member

Take a 30A dryer circuit, remove the 30A recept, put 6 50 on. Change breaker to 50, got a legal welder circuit but not legal dryer circuit.

Dryer still uses the same current under either breaker but internals not designed for short circuit demands of 50

Dryer still uses the same current under either breaker but internals not designed for short circuit demands of 50

Sberry

Platinum Member

I appologixe a little here. We orking is one of yhe best members here, i resd his posts, he knows more about most yhings yhan i do snd more about tractors than i evrr will.

Sberry

Platinum Member

My frustration comes from my inability to explain why it is allowed vs coming up eith my own rstionalixation as to why its not.

It would also be different if 1 engineer thoigjt yhis all the way thru but collectively over a long time is a diffetent matter and i still find simple stuff hadnt even ovcirrf to me how they do all this and rven how intricate the plug snd recept system is.

It would also be different if 1 engineer thoigjt yhis all the way thru but collectively over a long time is a diffetent matter and i still find simple stuff hadnt even ovcirrf to me how they do all this and rven how intricate the plug snd recept system is.

Sberry

Platinum Member

There are srveral aspects to pvrrvurrent on the simple 15A 120 dont occur to most people. Might be hardrr to explain to someone knows something about it.

Its worth yhe study of a 15 and 20 plug and recrpt

Breaker, supply wire is identical to 20A with 15 outlets. Change the end on a 20 to 15, nothing chsnges, the minimum circuit could be 15 and it would simply trip the breaker, a singlr load would trip a 20 on thrrmal before overheati g a 14 but reason to use 20 ends is to prevent it from being on a general. You can install a 20A on a general and all it does is say , its ok to plug the machine you have installed a 20 end on it in here

Its worth yhe study of a 15 and 20 plug and recrpt

Breaker, supply wire is identical to 20A with 15 outlets. Change the end on a 20 to 15, nothing chsnges, the minimum circuit could be 15 and it would simply trip the breaker, a singlr load would trip a 20 on thrrmal before overheati g a 14 but reason to use 20 ends is to prevent it from being on a general. You can install a 20A on a general and all it does is say , its ok to plug the machine you have installed a 20 end on it in here

- Status

- Not open for further replies.