Eagleview

Veteran Member

Over the years , I have accumulated a few bits and pieces that I have decided to glue together and end up with a tracked Mulcher .

The object of the plan is to use what I have at home and only buy in parts like hydraulic pumps , valve bodies , hoses etc .

I have a new cabin off of an articulated road roller that I picked up for near nothing that was still in the factory crate . While I was picking it up from the business that sold it to me , I noticed a new articulated front end loader bonnet in a crate . I made them a silly offer and they helped me load it up . :thumbsup:

I ended up with 4 new track frames and tracks from a rock crusher/screen supplier that have been sitting around for years at home .

Then I bought a 4 cylinder Diesel 175hp Nissan UD truck engine with only 90,000k's on the clock for a job but never happened .

The other day , I am looking at all this stuff and thought, bugger it , i'll build a mulcher ! (as you do)

Hope you get a kick out of the build , but please dont think it will take a week to do it . You could be in for a wait but these few picks will wet your appetite .

Day 1 .

Looking, Looking .

Day 2/3/4/5

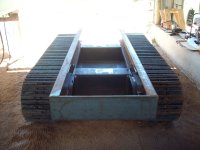

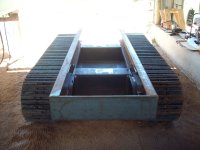

Cut the centers out of two of the track frames to use as cross members to join the remaining two . I didn't want to use box section as it is too torsionally stiff . These sections are "U" shaped with internal gussets etc and they can flex without cracking welds etc . Also built the Channel section intermediate chassis which will carry the cabin , bonnet , engine etc . Turned it all over in the dirt so I could fit the belly plate to the bottom .

Day 6

Fitted the rollers, idlers, track motors and tracks and turned it back over . It was then cleaned and scull dragged into the shed .

Day 7 (today 25/3/16)

Cabin and bonnet lifted on to the upper chassis . The cabin will be 8 inches higher when the cross members are welded in and the rubber mounts are in place .

The object of the plan is to use what I have at home and only buy in parts like hydraulic pumps , valve bodies , hoses etc .

I have a new cabin off of an articulated road roller that I picked up for near nothing that was still in the factory crate . While I was picking it up from the business that sold it to me , I noticed a new articulated front end loader bonnet in a crate . I made them a silly offer and they helped me load it up . :thumbsup:

I ended up with 4 new track frames and tracks from a rock crusher/screen supplier that have been sitting around for years at home .

Then I bought a 4 cylinder Diesel 175hp Nissan UD truck engine with only 90,000k's on the clock for a job but never happened .

The other day , I am looking at all this stuff and thought, bugger it , i'll build a mulcher ! (as you do)

Hope you get a kick out of the build , but please dont think it will take a week to do it . You could be in for a wait but these few picks will wet your appetite .

Day 1 .

Looking, Looking .

Day 2/3/4/5

Cut the centers out of two of the track frames to use as cross members to join the remaining two . I didn't want to use box section as it is too torsionally stiff . These sections are "U" shaped with internal gussets etc and they can flex without cracking welds etc . Also built the Channel section intermediate chassis which will carry the cabin , bonnet , engine etc . Turned it all over in the dirt so I could fit the belly plate to the bottom .

Day 6

Fitted the rollers, idlers, track motors and tracks and turned it back over . It was then cleaned and scull dragged into the shed .

Day 7 (today 25/3/16)

Cabin and bonnet lifted on to the upper chassis . The cabin will be 8 inches higher when the cross members are welded in and the rubber mounts are in place .

Last edited: