Rustyiron

Super Member

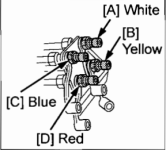

Threw these together during shop time with all the recent snow. It seems lately that all my hyd. attachments are needing me to "crack a line" to release about a tsp. of fluid to connect them. Very frustrating, and yes I know how to release the pressure before you disconnect. I'm convinced that it only takes a few degrees of temp. difference to expand the fluid and create enough pressure to make it impossible to do. Pretty simple, for the male end I just made a slot to hold the fitting in one of the recessed groove and use a bolt to screw into the middle part to release the pressure. The female side I found an old socket that fit (with a little grinding) into the proper "ring" on the face and plunger that is hand activated. They seem to work well so far.