kdlklm

Silver Member

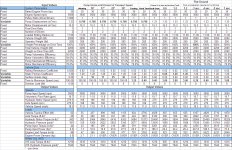

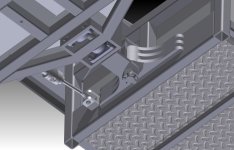

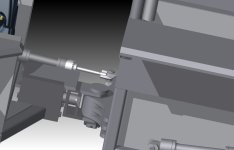

I'm building a custom UTV, it has a lowering front-end so it can be accessed by someone in a wheelchair. The photo only shows the front half, it uses articulated steering. I want each wheel to be able to retract independently, ultimately I want to get rid of the bolt on the end of the shaft that holds the motor mount. I would like it to be as narrow as possible. So I would like to do away with the bolt and welded the motor mount directly onto the shaft. I'm looking for some suggestions on how to reconfigure the shaft so each wheel and motor can be independently moved. And it also needs to be able to be taken apart for maintenance.

Thanks guys

Thanks guys