shona13

Gold Member

- Joined

- May 5, 2012

- Messages

- 367

- Tractor

- Massey Ferguson 148 .Chamberlain Super 70. Caterpillar D4. Chamberlain 354 FEL.Toro 268 rideon kubota L2002fel

G'day Coyote machine.

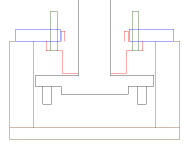

The drawing is to give an idea as to how everything goes together ,Although it does show a nice flat surface Under the bearing hub , it is fairly uneven plus the casting where the retaining studs go through are a bit uneven also there is not a lot of space between the hub and flange again the illustration is just to show how the Flange should be used.

the Flange is one piece and would be drilled to accomodate the hub retaining Studs/Bolts!

Happy Days.

Hutch.

The drawing is to give an idea as to how everything goes together ,Although it does show a nice flat surface Under the bearing hub , it is fairly uneven plus the casting where the retaining studs go through are a bit uneven also there is not a lot of space between the hub and flange again the illustration is just to show how the Flange should be used.

the Flange is one piece and would be drilled to accomodate the hub retaining Studs/Bolts!

Happy Days.

Hutch.

Last edited: