You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what are the four holes for in the bottom of the TO-30 differential case?

- Thread starter dbotos

- Start date

- Views: 21117

/ what are the four holes for in the bottom of the TO-30 differential case?

#71

Coyote machine

Super Member

- Joined

- May 4, 2009

- Messages

- 7,641

- Location

- Southern VT

- Tractor

- 22 SANY SY 50U, '10 Kioti DK 40se/hst KL-401 FEL, loaded tires, KB-2485 bhoe, Tuffline TB160 BB, Woods QA forks, MIE Hydraulic bhoe thumb & ripper tooth, Igland 4001 winch, & GR-20 Log Grapple. Woods BBX72" Brush Mower. Diamondplate aluminum canopy

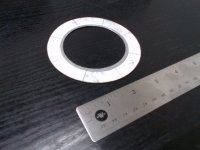

Started making a sheet metal (0.030") bearing shield today at lunch. Figured it'd hold up better than the cardboard one, especially if I need to put the heat gun to the collar. Just need to finish up the ID with the die grinder.

View attachment 353915

Nice work. At this point I'd put a call in to Axemen for Joey to come over and tear up the rest of that collar!:laughing:

Is there a way you could get the shaft and collar angled so your milling machine could cut under the shield of the retainer so you could get to more of the collar's width toward the bearing? If not can you re-position and duplicate what you did to the collar at 180*? This could make controlled air pressure on an air chisel finish the job...

Thanks. Haven't seen that show in a while - used to watch it before getting rid of the TV part of cable.

I thought about angling it, but didn't have a good way to do it. Got a little 4" vise on that 6 x 26 mill, whose jaws are just tall enough to hold the shaft comfortably given the size of the flange on the outboard end. If I had a nice big angle plate, I'd clamp it to that at an angle.

Milling the opposite side of the collar would be pretty easy. The steel seems pretty plain-jane and cut without any trouble. I may have to resort to that depending on how trying to get it with just this one area goes.

I thought about angling it, but didn't have a good way to do it. Got a little 4" vise on that 6 x 26 mill, whose jaws are just tall enough to hold the shaft comfortably given the size of the flange on the outboard end. If I had a nice big angle plate, I'd clamp it to that at an angle.

Milling the opposite side of the collar would be pretty easy. The steel seems pretty plain-jane and cut without any trouble. I may have to resort to that depending on how trying to get it with just this one area goes.

Coyote machine

Super Member

- Joined

- May 4, 2009

- Messages

- 7,641

- Location

- Southern VT

- Tractor

- 22 SANY SY 50U, '10 Kioti DK 40se/hst KL-401 FEL, loaded tires, KB-2485 bhoe, Tuffline TB160 BB, Woods QA forks, MIE Hydraulic bhoe thumb & ripper tooth, Igland 4001 winch, & GR-20 Log Grapple. Woods BBX72" Brush Mower. Diamondplate aluminum canopy

I would think cutting it in 2 or even 3 places might ease the final tweaking of getting it to let go, and could be a lot less effort=time too. JMHO:confused3:

The kid

Elite Member

- Joined

- Apr 25, 2012

- Messages

- 3,888

- Location

- Middle Tennessee

- Tractor

- 1965 135 gasser, 1967 135 diesel

You would do better with a torch. Even a propane torch. i prefer MAP gas torch. Hotter. A flame will penetrate faster and yield the results you seek. Those bearing should shatter when struck with a chisel. -kidI've got a 1200-Watt heat gun that does 1100 deg F on high, 650 on low. I might try wrapping some insulation around the shaft and blasting the collar with that (with one of the concentrator tips installed).

Mike476

Veteran Member

- Joined

- Jun 6, 2010

- Messages

- 1,080

- Location

- Annapolis Valley, Nova Scotia

- Tractor

- MF 135 Z134 Continental, MF 1660 Cab

I would try a well placed blow or two with a chisel. Once split if it still doesn't want to move I'd look at heating it up.

Got the sheet metal bearing shield done. Making stuff like this by hand is tedious. Well, at least the ID was...

Coyote - I'm hoping thinning out just the one spot will get it to stretch or break enough to get it off - hopefully I'll get lucky.

kid - I may resort to some sort of torch if the heat gun doesn't work. Just trying to baby step it so I don't overdo it and mess up one of the expensive parts.

Mike - I'd feel comfortable with a tangetial hit to break the thin section, but I'd be nervous doing it radially for fear of it continuing on through and nicking the shaft.

Coyote - I'm hoping thinning out just the one spot will get it to stretch or break enough to get it off - hopefully I'll get lucky.

kid - I may resort to some sort of torch if the heat gun doesn't work. Just trying to baby step it so I don't overdo it and mess up one of the expensive parts.

Mike - I'd feel comfortable with a tangetial hit to break the thin section, but I'd be nervous doing it radially for fear of it continuing on through and nicking the shaft.

Coyote machine

Super Member

- Joined

- May 4, 2009

- Messages

- 7,641

- Location

- Southern VT

- Tractor

- 22 SANY SY 50U, '10 Kioti DK 40se/hst KL-401 FEL, loaded tires, KB-2485 bhoe, Tuffline TB160 BB, Woods QA forks, MIE Hydraulic bhoe thumb & ripper tooth, Igland 4001 winch, & GR-20 Log Grapple. Woods BBX72" Brush Mower. Diamondplate aluminum canopy

Got the sheet metal bearing shield done. Making stuff like this by hand is tedious. Well, at least the ID was...

View attachment 354255

Coyote - I'm hoping thinning out just the one spot will get it to stretch or break enough to get it off - hopefully I'll get lucky.

kid - I may resort to some sort of torch if the heat gun doesn't work. Just trying to baby step it so I don't overdo it and mess up one of the expensive parts.

Mike - I'd feel comfortable with a tangetial hit to break the thin section, but I'd be nervous doing it radially for fear of it continuing on through and nicking the shaft.

I'm not certain what the radial hit and possible nick on the shaft would do to make the whole assembly compromised?

My understanding is the collar is merely a bearing retainer and nothing more. A possible nick or even a gouge should not make any real difference overall. Grease is held in place by the failed outer bearing seal and the collar has no influence on that. That collar is on the shaft so tight, a nick, gouge or whatever is likely to be insignificant in relation to the new collar's ability to hold the bearing in the hub/retainer.

I'm in full agreement to use heat from a Mapp gas torch or cutting torch to cut the thing loose, or do the opposite edge milling. I do have doubts about it breaking loose by just one side cut like you have going. Plus it would take a lot more than anything you might throw at the shaft to damage it to the point of dis-guarding it. JMHO.

BTW, I'm curious why you have not tried using a press, as suggested earlier to press the collar off while applying heat to the collar? It seems like a really sound method to get it done?

Success - I got it off with out damaging the shaft or the bearing!  And I learned a new trick - will get to that in a minute.

And I learned a new trick - will get to that in a minute.

So first I removed what material from the collar I could on the mill. Then the portion that was shadowed by the shoulder of the casting got attacked with Dremel cut-off wheels and a 3" cutting disk on the die grinder (the latter had better "reach" down in there). The metal bearing shield and bottomless steel can made for adequate protection of the bearing and the exposed finished portion of the shaft, respectively. Once I had removed most of the material from the collar in that one spot (leaving thin sections against the shaft and bearing), I thought about how to get the thin section to split apart. I took the Dremel cut off wheel and tired to make a shallow cut running in the axial direction along the surface of the thin section (hoping the discontinuity in the surface would initiate a split). Couldn't quite get it in there to make that happen, so I turned to the chisel. Laid it almost parallel to the shaft and tried to gouge the surface of the thin section to get it to split. Chisel wasn't quite right either, but it did lead me to the trick that worked...

On the little bit I was able to get at with the chisel, I noticed it was pushing material to the sides. The chisel blade was too wide/flat for the contour of the ground surface - I needed something more concentrated that I could get in there with. Enter the center punch. I used the center punch along the thin section to peen the material outwards and stretch it enough that the collar just loosened up and was able to slide off the axle. After I got it off, I cut through the opposite side of the collar and snapped the thin section to see just how thin I had gotten it. You can see, it's roughly an "L" shape with the corner a little thicker than the ends (the grayish part inside the thin "L" is just the ground surface that's curving away from the thin section due to the round cutting disks):

Bearing removal up next.

So first I removed what material from the collar I could on the mill. Then the portion that was shadowed by the shoulder of the casting got attacked with Dremel cut-off wheels and a 3" cutting disk on the die grinder (the latter had better "reach" down in there). The metal bearing shield and bottomless steel can made for adequate protection of the bearing and the exposed finished portion of the shaft, respectively. Once I had removed most of the material from the collar in that one spot (leaving thin sections against the shaft and bearing), I thought about how to get the thin section to split apart. I took the Dremel cut off wheel and tired to make a shallow cut running in the axial direction along the surface of the thin section (hoping the discontinuity in the surface would initiate a split). Couldn't quite get it in there to make that happen, so I turned to the chisel. Laid it almost parallel to the shaft and tried to gouge the surface of the thin section to get it to split. Chisel wasn't quite right either, but it did lead me to the trick that worked...

On the little bit I was able to get at with the chisel, I noticed it was pushing material to the sides. The chisel blade was too wide/flat for the contour of the ground surface - I needed something more concentrated that I could get in there with. Enter the center punch. I used the center punch along the thin section to peen the material outwards and stretch it enough that the collar just loosened up and was able to slide off the axle. After I got it off, I cut through the opposite side of the collar and snapped the thin section to see just how thin I had gotten it. You can see, it's roughly an "L" shape with the corner a little thicker than the ends (the grayish part inside the thin "L" is just the ground surface that's curving away from the thin section due to the round cutting disks):

Bearing removal up next.

Coyote machine

Super Member

- Joined

- May 4, 2009

- Messages

- 7,641

- Location

- Southern VT

- Tractor

- 22 SANY SY 50U, '10 Kioti DK 40se/hst KL-401 FEL, loaded tires, KB-2485 bhoe, Tuffline TB160 BB, Woods QA forks, MIE Hydraulic bhoe thumb & ripper tooth, Igland 4001 winch, & GR-20 Log Grapple. Woods BBX72" Brush Mower. Diamondplate aluminum canopy

Nice result!:drink:

Now time for the press!:thumbsup::2cents:

Now time for the press!:thumbsup::2cents: