joshuabardwell

Elite Member

No, not my nuts. :laughing:

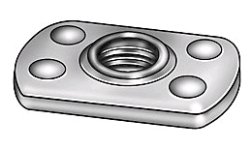

I'm making a toy for my 17-month-old son. He loves playing with wrenches and nuts and bolts, so I figured I would make him a plate of metal with some captive bolts and a box wrench on a chain, so he can turn the bolts but neither they nor the wrench could get separated. It's a pretty rudimentary project, and once upon a time, I would have made it out of wood, but I'll take any chance I can get to practice welding.

My idea was that I would drill holes in a plate, then weld nuts over the holes, then put bolts through the nuts, then weld washers onto the end of the bolts to prevent them from being removed. The problem I ran into was, after welding the nuts on, the bolts wouldn't go all the way through two out of the three of them. At first, I thought maybe a little slag or dust got into the threads, but upon closer inspection, they looked like they might be warped or distorted from the heat. For perspective, I used 3/32" E7014 at about 110 amps, DCEP. The base plate is about 3/16" to 1/4" thick and the bolts and nuts are 9/16" (3/8" diameter thread).

As a workaround, I am considering putting the bolts through the plate and then welding the heads of the bolts to the back of the plate, but I really like the idea of having the bolts being turned through the plate, compared to having the nuts being turned up and down the bolts, so I'd rather find a way to affix the nuts to the plate without damaging them. I suppose I could just break down and use JB-weld, but I didn't buy a welder just go turn around and JB-weld something, now did I!

I'm making a toy for my 17-month-old son. He loves playing with wrenches and nuts and bolts, so I figured I would make him a plate of metal with some captive bolts and a box wrench on a chain, so he can turn the bolts but neither they nor the wrench could get separated. It's a pretty rudimentary project, and once upon a time, I would have made it out of wood, but I'll take any chance I can get to practice welding.

My idea was that I would drill holes in a plate, then weld nuts over the holes, then put bolts through the nuts, then weld washers onto the end of the bolts to prevent them from being removed. The problem I ran into was, after welding the nuts on, the bolts wouldn't go all the way through two out of the three of them. At first, I thought maybe a little slag or dust got into the threads, but upon closer inspection, they looked like they might be warped or distorted from the heat. For perspective, I used 3/32" E7014 at about 110 amps, DCEP. The base plate is about 3/16" to 1/4" thick and the bolts and nuts are 9/16" (3/8" diameter thread).

As a workaround, I am considering putting the bolts through the plate and then welding the heads of the bolts to the back of the plate, but I really like the idea of having the bolts being turned through the plate, compared to having the nuts being turned up and down the bolts, so I'd rather find a way to affix the nuts to the plate without damaging them. I suppose I could just break down and use JB-weld, but I didn't buy a welder just go turn around and JB-weld something, now did I!