mike69440

Elite Member

- Joined

- Jun 2, 2005

- Messages

- 3,377

- Location

- Central NH (God's Country)

- Tractor

- 2005 L39 Kubota, 2020 Polaris 570 Sportsman, 2006 RTV 900, 2019 RTV1100C, 1997 Komatsu PC75UU2E w/ Thumb & Blade, 2013 Mahindra Max28XL Shuttle plus many attachments

Reworking the cylinders; Re: Weak Loader Curl Possible Solution For the Max28

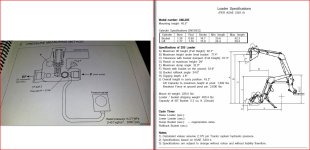

Sunday I ordered (4) #6 SAE to #4 JIC adapters from Surplus Center for the 1526L loader curl cylinders to adapt them to the Max28 hoses. I also got with a few other fitting and a 0-3000 psig pressure gage to replace the 5000 Psi gage. The 5000 psig gage I'll mount permanent on my L39 Kubota.

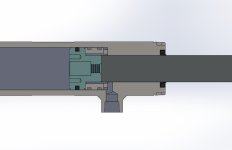

Today I machined the cross tubes to fit the ML205 loader. I will test fit the cylinders to verify that my stroke limiter dimensions are correct before I ask the shop to cut them. The Pin holes are 1" and the Pins are 25mm. I will probably line the cross tube bores with shim stock to take out the 1/64" extra play. The 40mm cylinders from the 1526L do not look much bigger than the 35mm OEM ML205 pieces, but the retract force increases 56%.

PS I looked over some tractors Saturday when I picked up my cylinders:

The Max26 curved loader uses smaller 20mm pins than my ML205 loader and the gussets are thinner by almost 50%. I do like the quick attach but not the other cost reductions. The ML205 itself is not really all that structurally stiff.

The eMax comes with a 25 L loader and a a 25 L S loader. The 25 L S loader is much better built with a 4 link bucket attach and heavier gussets. I actually like the 25L S loader better than the loaders on the Max24 or Max26.

People buying a new tractor might consider these aftermarket loaders, that are a cut above OEM

TA-54: Westendorf Front-End Tractor Loader

Sunday I ordered (4) #6 SAE to #4 JIC adapters from Surplus Center for the 1526L loader curl cylinders to adapt them to the Max28 hoses. I also got with a few other fitting and a 0-3000 psig pressure gage to replace the 5000 Psi gage. The 5000 psig gage I'll mount permanent on my L39 Kubota.

Today I machined the cross tubes to fit the ML205 loader. I will test fit the cylinders to verify that my stroke limiter dimensions are correct before I ask the shop to cut them. The Pin holes are 1" and the Pins are 25mm. I will probably line the cross tube bores with shim stock to take out the 1/64" extra play. The 40mm cylinders from the 1526L do not look much bigger than the 35mm OEM ML205 pieces, but the retract force increases 56%.

PS I looked over some tractors Saturday when I picked up my cylinders:

The Max26 curved loader uses smaller 20mm pins than my ML205 loader and the gussets are thinner by almost 50%. I do like the quick attach but not the other cost reductions. The ML205 itself is not really all that structurally stiff.

The eMax comes with a 25 L loader and a a 25 L S loader. The 25 L S loader is much better built with a 4 link bucket attach and heavier gussets. I actually like the 25L S loader better than the loaders on the Max24 or Max26.

People buying a new tractor might consider these aftermarket loaders, that are a cut above OEM

TA-54: Westendorf Front-End Tractor Loader

Attachments

Last edited: