Any way to easily figure out the speed changes?

Having been there, done that, the short answer is "NO" to the "easy" part. With a variable displacement pump, the inherent loss of efficiency in hydraulic systems, etc. -- all you can end up with it theoretical numbers.

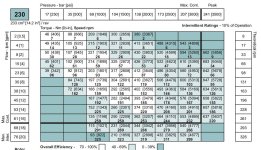

However, the White catalogs list the specs for each size motor in a series separately, with a table for different flow rates (volume) and PSI. So, you can compare the specs, side by side, at different pressure and flow ratings. I built a spreadsheet that compared the numbers for the specific size motors I was looking at, using the data from those tables. Disregard any numbers above 2500 PSI (max limit for these PT designs, AFAIK), and about 12 GPM (though I'm not sure what the theoretical max for this tram pump is). Then you could use tire circumference to calculate the theoretical MPH. Since we're dealing with theoretical numbers, it is essentially a direct relationship. Twice the displacement yields twice the torque, and 1/2 the RPM (speed).

From practical experience in having done this twice now, and seat-of-the-pants observations, the CE-series 22.8ci would be a good choice to meet your stated requirements, if you plan on staying with the stock 23x10.50x12 tires. I ran CharLynn S-series motors about that size for a while -- though I don't recommend them for this conversion because the taper on their tapered shafts does NOT match the taper on the PT hubs. I couldn't keep the hubs tight, and wallowed them out -- they're very soft metal.

I'm now running White RE-series 28.3ci BUT I also went to 26x12x12 tires. Even with the taller tires it is SLOW (slower than your stated goal) but has more torque that the 425's design limits -- I've bent QA hitches, lift arms, etc. I have to be careful not to break things, and still find the weak points in the PT's design. So far, I love the torque on my steep hillsides, though, and have found the speed "fast enough" even if I am mowing at full treadle on the few flat spots I have.

As I said, I'd recommend the 22.8 size -- then you could go to taller tires if you wanted more speed...

BTW, my only complaint with the RE series wheel motors is that I have now blown the seals on each of the rear wheel motors. The first one went at about 250-300 hours of abuse, and simply ordered another wheel motor from Surplus Center to have a spare. The second one went yesterday, and I just ordered two seal kits. I'll have one put in the wheel motor I replace initially, then have to second one installed in the motor that just blew, so I'll have a ready spare next time...Surplus Center no longer has the REs in this size in stock (sold out, I guess) but at $179 each (with hubs) or $169 each (without hubs) they were a bargain while they lasted....