Shield Arc

Super Member

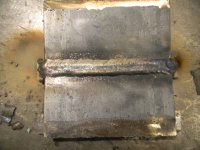

A member on another site shipped me some AC/DC 7018, asked if I would run a bend test to see the results. Far as I know this rod has never seen the inside of an oven. At the very end of the root pass the rod acted really funny, I could see the flux flaking off 3/4 to 1-inch above the puddle . I don't think I had the wrong rod angle, because this isn't my first rodeo

. I don't think I had the wrong rod angle, because this isn't my first rodeo ! Even with this rod being cold, it ran very nice, maybe the best 7018 I have ever run!

! Even with this rod being cold, it ran very nice, maybe the best 7018 I have ever run!

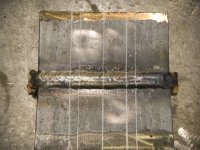

I'll cut and bend the coupons tomorrow morning, and post the results.

Welcome to Maintenance Technology Corp.

I'll cut and bend the coupons tomorrow morning, and post the results.

Welcome to Maintenance Technology Corp.