chrismac

Silver Member

I have come to the conclusion it will be best and easiest to keep all my questions regarding my project in the one place in this thread of my restoration of my TX2160 tractor, with a 2nd tractor for spares.

If this is in the wrong place please moderators please place in the correct part of the forum.

So first image is the tractor, its been sitting for many years out side abandoned, this was it half way home.

Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on Flickr

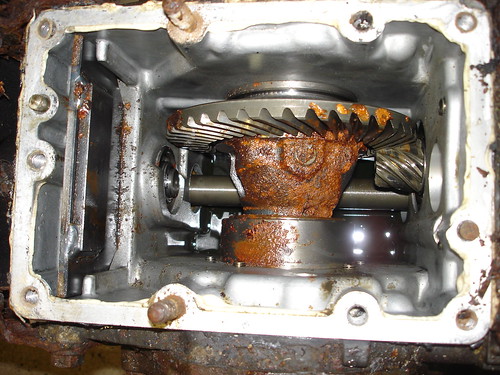

Then we had the 2nd tractor which was for spares, it is also in poor condition,

DSC02542 by chrismac2012, on Flickr

DSC02542 by chrismac2012, on Flickr

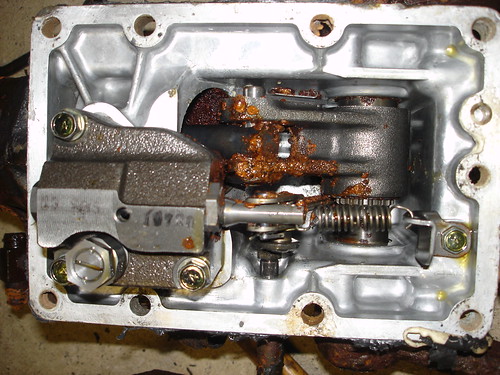

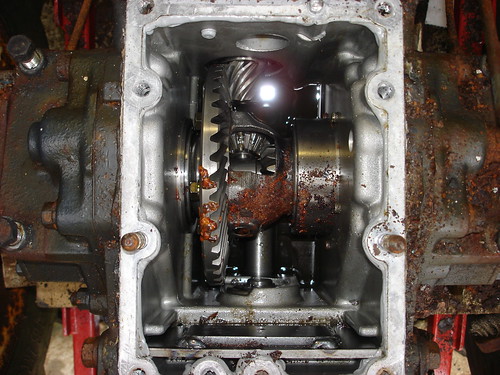

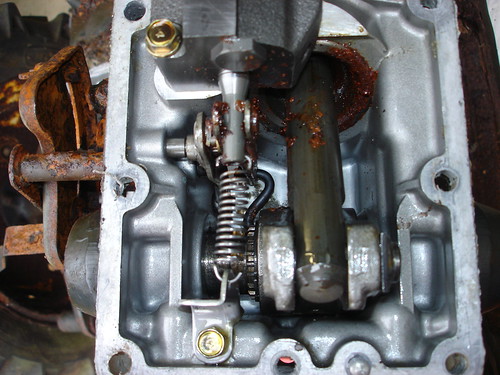

Engine out, injector pipes have been slackened and the nuts have rusted completly.

DSC02550 by chrismac2012, on Flickr

DSC02550 by chrismac2012, on Flickr

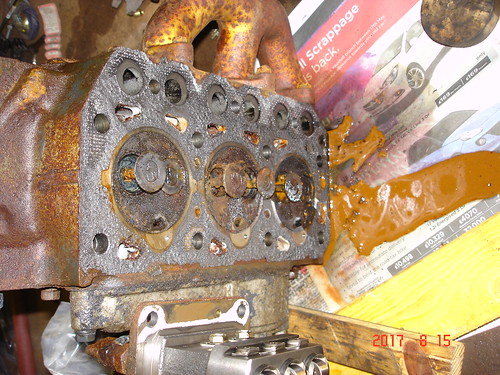

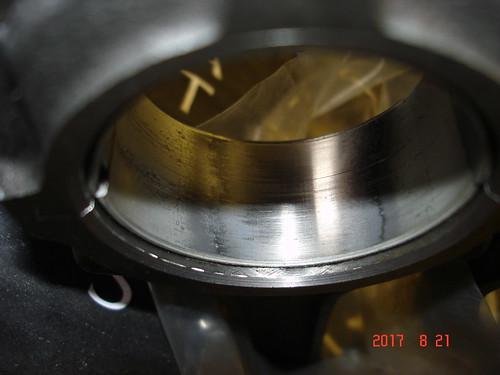

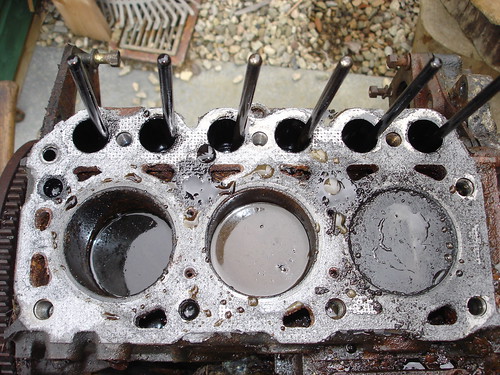

Cylinder head off, the pistons were stuck because of water ingress,

DSC02563 by chrismac2012, on Flickr

DSC02563 by chrismac2012, on Flickr

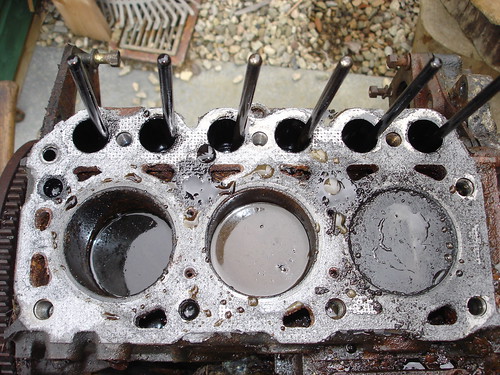

Cylinder head, quite a bit of pitting on the seats and valves, waiting to see what the 2nd engine is like before I commit to doing to much work on this.

DSC02566 by chrismac2012, on Flickr

DSC02566 by chrismac2012, on Flickr

I have been working on this for a few weeks now, there is more pictures to follow.

Chris

If this is in the wrong place please moderators please place in the correct part of the forum.

So first image is the tractor, its been sitting for many years out side abandoned, this was it half way home.

Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on Flickr Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on FlickrThen we had the 2nd tractor which was for spares, it is also in poor condition,

DSC02542 by chrismac2012, on Flickr

DSC02542 by chrismac2012, on FlickrEngine out, injector pipes have been slackened and the nuts have rusted completly.

DSC02550 by chrismac2012, on Flickr

DSC02550 by chrismac2012, on FlickrCylinder head off, the pistons were stuck because of water ingress,

DSC02563 by chrismac2012, on Flickr

DSC02563 by chrismac2012, on FlickrCylinder head, quite a bit of pitting on the seats and valves, waiting to see what the 2nd engine is like before I commit to doing to much work on this.

DSC02566 by chrismac2012, on Flickr

DSC02566 by chrismac2012, on FlickrI have been working on this for a few weeks now, there is more pictures to follow.

Chris